Introduction

Automated visual inspection systems (AVIs) are integral to pharmaceutical manufacturing, ensuring both product quality and regulatory compliance. However, traditional AVIs have a significant drawback: high false eject rates. These rates can reach up to 30%, leading to substantial yield loss and increased production costs.

The issue is especially pronounced with products that exhibit considerable variability, where AVIs struggle to differentiate between acceptable deviations and true defects. Beyond the financial impact, frequent false ejects can raise regulatory concerns, signaling potential inconsistencies in the inspection process or the underlying manufacturing operations.

Example of a difficult-to-inspect product

Why AVIs Are Prone to High False Eject Rates

The core issue with traditional AVIs lies in their technological limitations. It is challenging to program these systems to accommodate the wide range of normal variability in pharmaceutical products, resulting in an overreliance on broad rejection criteria.

When dealing with difficult-to-inspect products, such as molded glass vials or lyophilized cakes, traditional AVIs frequently misinterpret acceptable variations, like air bubbles or seams, as defects, leading to high rejection rates. The systems are programmed to err on the side of caution, rejecting units that would otherwise pass manual inspection.

Financial Impact of Yield Loss

Yield loss caused by false ejects can severely impact manufacturing costs, as both production expenses and the volume of rejected products contribute to the financial burden. A false eject rate of 4% may seem modest, but when scaled across high-volume production lines or high-value products, the cumulative cost can be significant.

This inefficiency not only increases the cost per unit but also reduces throughput. Additionally, from a regulatory perspective, consistently high rejection rates could signal deeper, systemic issues within the manufacturing or inspection process, potentially drawing increased scrutiny from regulators.

How Do Companies Cope with This Challenge?

Pharmaceutical manufacturers facing high false eject rates typically have two options: accept the yield loss or avoid using AVIs for certain product types altogether. In many cases, companies opt for manual or semi-automated inspection systems, which are labor-intensive and prone to human error. While this approach may work for low-production-volume or highly variable products, it is neither scalable nor sustainable for large-scale operations.

How AVIS Uniquely Addresses These Challenges

Boon Logic’s AI-based Visual Inspection System (AVIS™) overcomes the limitations of traditional AVIs by utilizing unsupervised machine learning. Unlike conventional systems that rely on pre-labeled defect images, AVIS builds a model by learning from normal variations in compliant units. This approach significantly reduces false eject rates by focusing on identifying true abnormalities rather than filtering out defects based on rigid, predefined rules.

For example, in a feasibility study involving powder-filled molded glass vials, AVIS reduced the false eject rate to just 3% while achieving a detection accuracy of over 98%. By learning from acceptable product variations—such as clumps or powder adhesion inside molded glass vials—AVIS minimizes unnecessary rejections. This not only reduces yield loss but also lowers the total cost of system ownership by eliminating the need for extensive retraining and model fine-tuning.

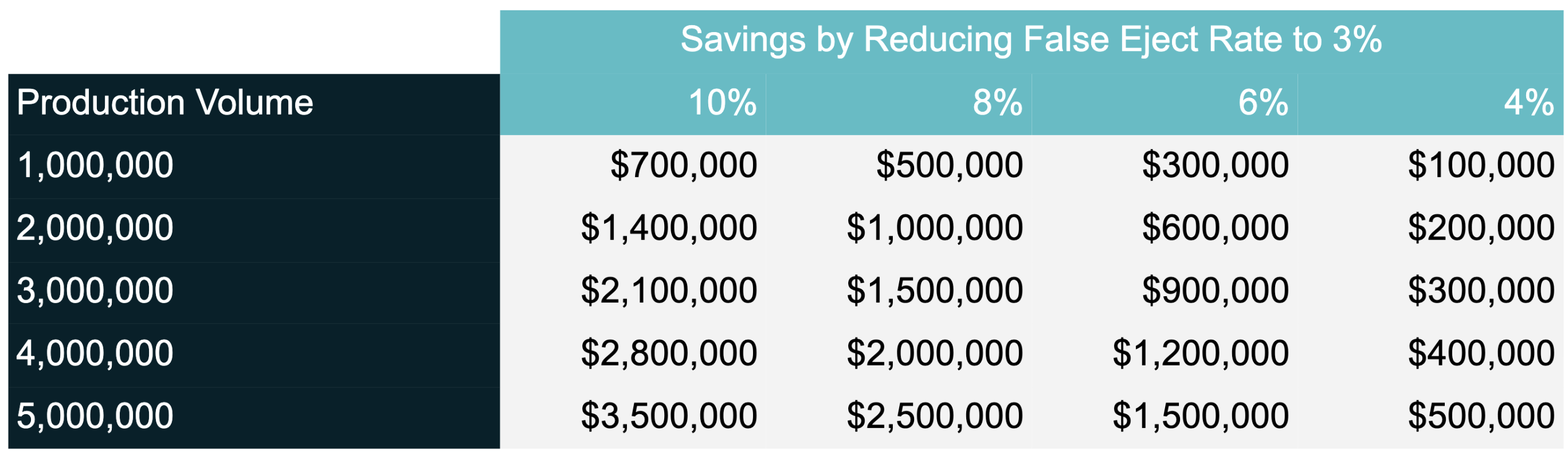

Cost Savings from Reducing False Eject Rates with AVIS

The chart below highlights the potential cost savings achieved by reducing the false eject rate from initial levels of 10%, 8%, 6%, and 4% to 3% using AVIS, based on a conservative manufacturing unit cost of $10.

Assumes a unit manufacturing cost of $10/unit

Conclusion

The high false eject rates of traditional AVIs create significant operational and financial burdens for pharmaceutical manufacturers. By leveraging AVIS, companies can overcome these challenges through advanced anomaly detection, minimizing yield loss and improving product quality. AVIS provides a more precise, efficient, and cost-effective solution, particularly for difficult-to-inspect products.