Real Machine Learning for Asset Health Monitoring

Amber detects anomalies in complex assets and environments by autonomously training for the normal instead of the abnormal.

5 minutes

Time to create a model from scratch

6 weeks

Average warning before asset failure

Any user

No data science skills required to build ML models

Any platform

Plugin for any IoT platform

Enhance reliability with AI-driven insights

Make smarter decisions with complete visibility into the health of your operations. Amber detects equipment noncompliance earlier than any other predictive analytics tool, giving you more time to schedule maintenance, order parts, or change production settings, all with data from your existing historian.

Accurate prediction

Detect early signs of failure as soon as they occur without annoying false alarms

Easy to use

ML designed to be configured by reliability engineers and plant staff

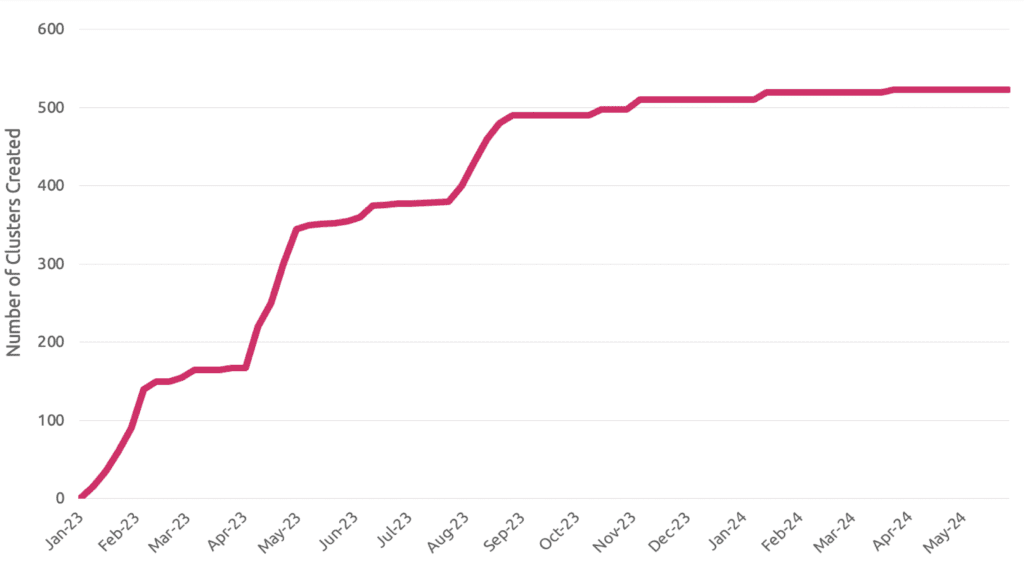

Quick to scale

Deploy thousands of models in weeks

Complete visibility into your equipment health

Finding the abnormal is easy once you understand normal. Even with the most complex equipment, Amber trains from data collected during normal operations, instead of relying on failure modes and programmed logic. Starting from normal is the only way to have insights you can truly trust.

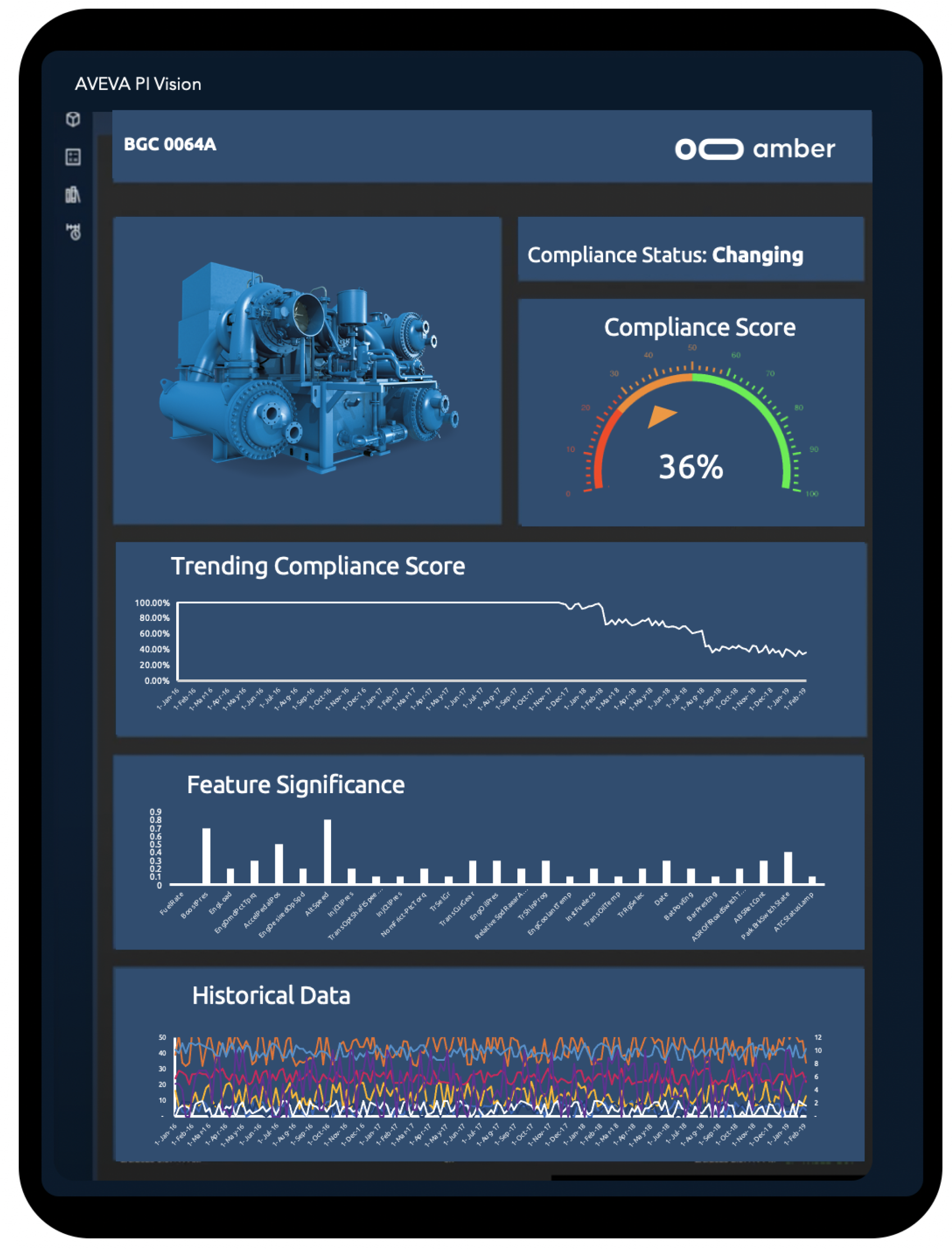

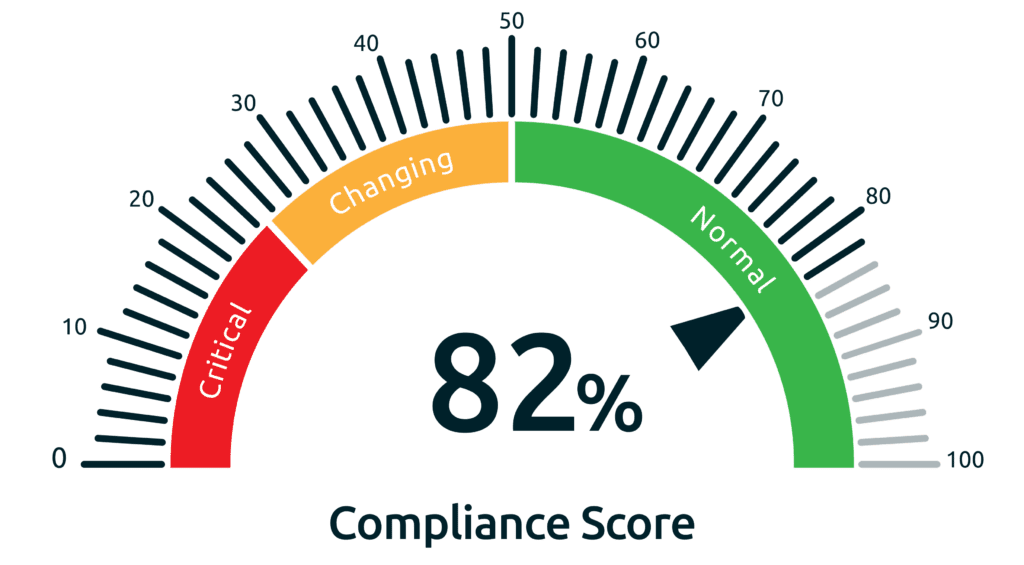

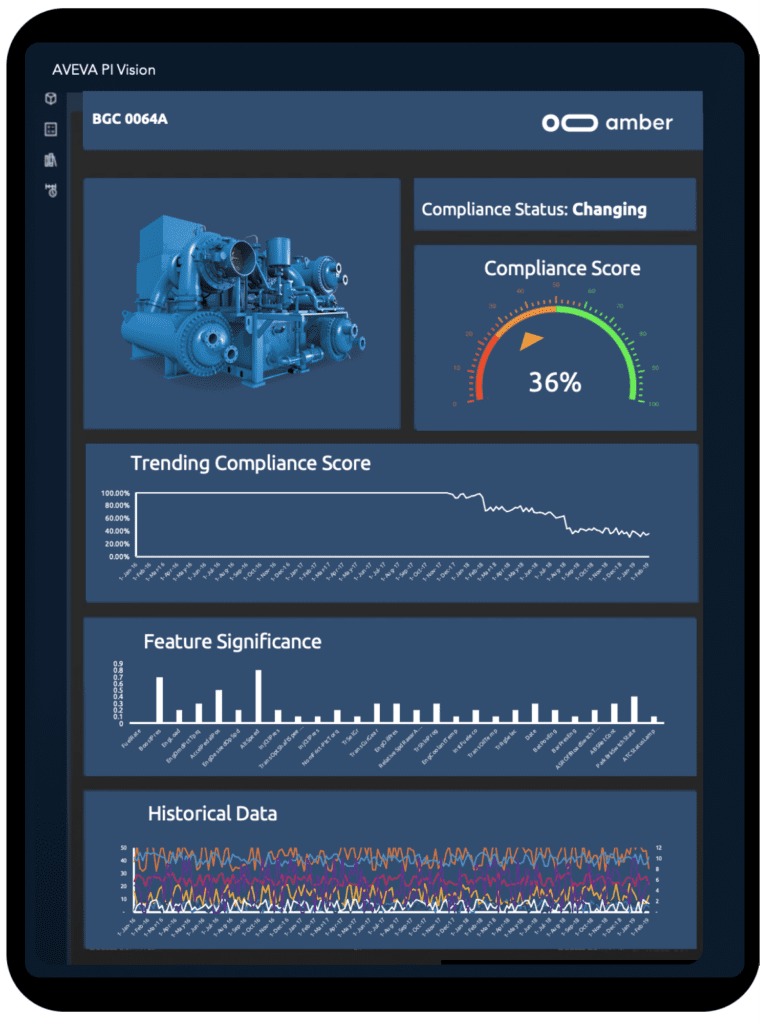

Amber’s Compliance Score is based on an individualized, high-dimensional, unsupervised machine learning model of your asset. The score indicates ongoing asset health and deviations from normal operating behavior.

Normal: 51% - 100%

Changing: 26% - 50%

Critical: 0% - 25%

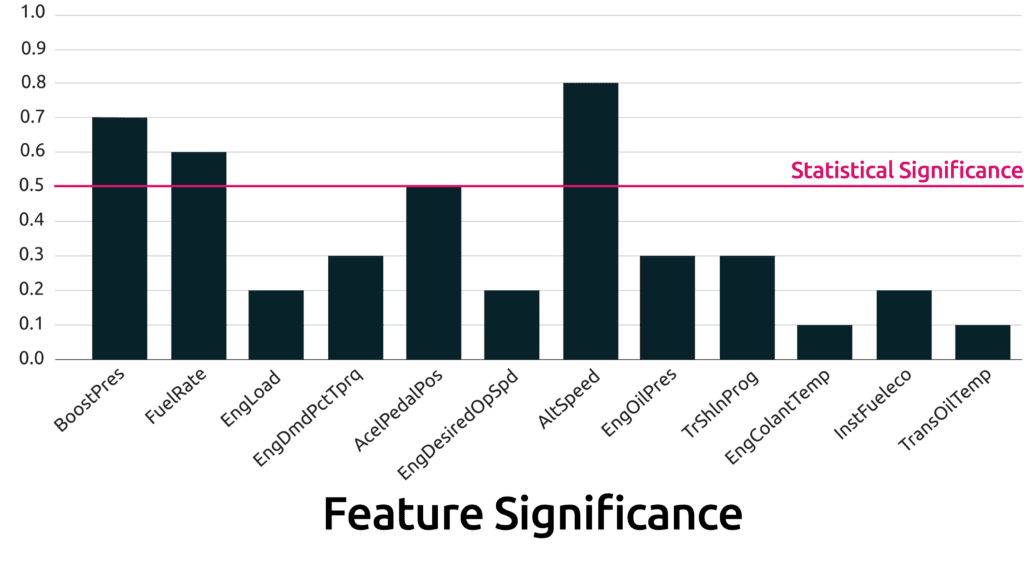

Insight into the source of the problem

Feature Significance sheds light on which features are the culprits in causing a drop in Compliance Score. Being able to swiftly pinpoint the origin of the problem allows for prompt and cost-effective issue resolution.

Three steps to deployment

Configure

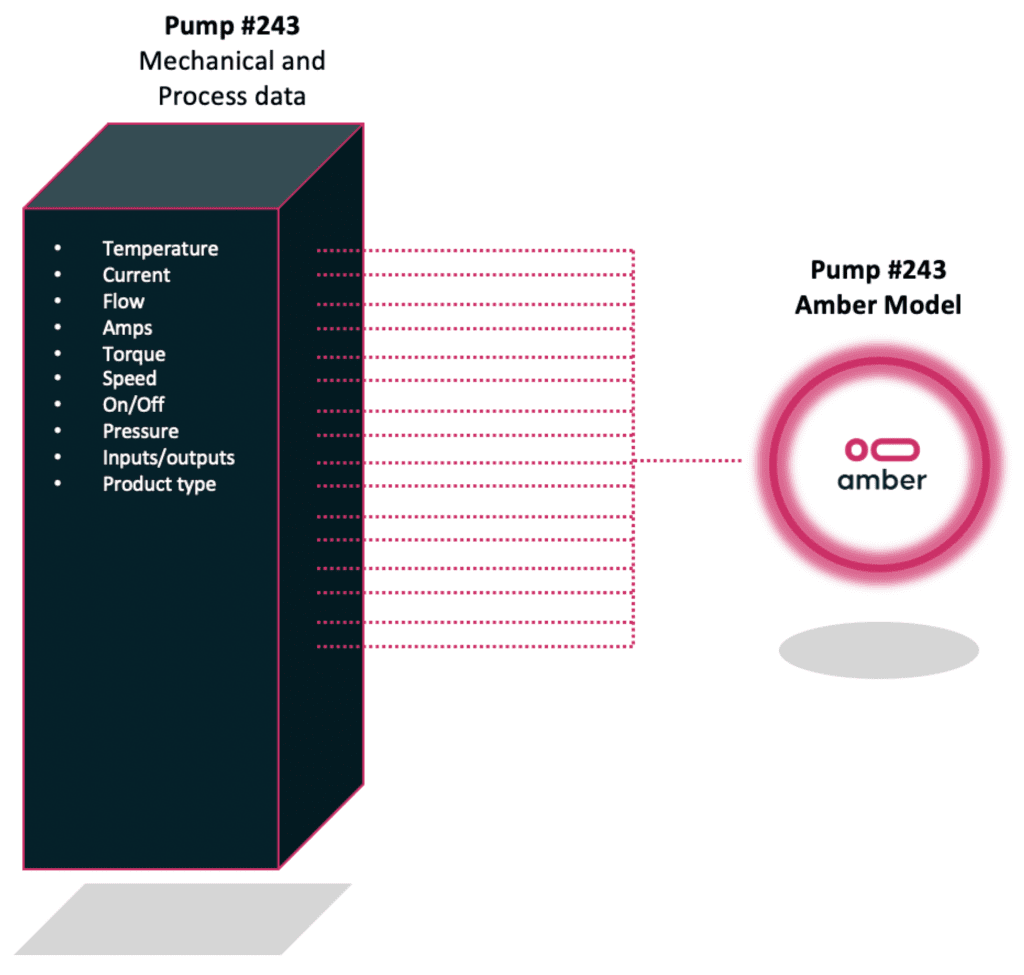

To configure Amber, choose 1– 500 tags to be incorporated into a model. The selected tags should be related to the health of the equipment or process. Amber will learn the relationships that exist between the tags during training.

Types of tags to include:

- Production inputs and outputs

- Equipment settings

- On/off

- Temperature

- Current

- Flow

- Speed

- Pressure

- Displacement measurements

Train

Amber’s auto-learning algorithm trains itself, enabling deployment in minutes, not weeks. During training, Amber learns hundreds of relationships between the tags selected during configuration. As training progresses, Amber’s learning curve starts to level, indicating that Amber is becoming familiar with the asset’s normal operations. Once the learning curve plateaus, training is complete.

- Trains a unique model from scratch for each asset

- No programming required

- No data scientist required

Monitor

After training concludes, Amber seamlessly shifts into monitoring mode. Throughout this phase, streaming data is assessed against the model established during training. For every sample, a Compliance Score and Feature Significance are generated. Samples closely resembling the model yield higher Compliance Scores, whereas significantly deviating samples result in lower Compliance Scores.

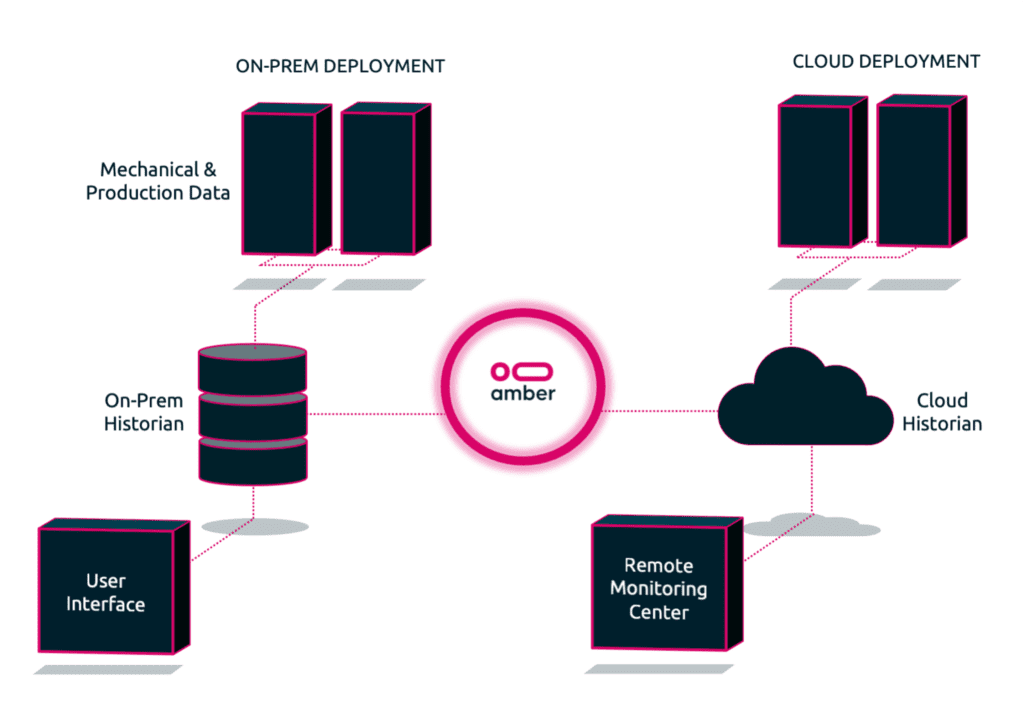

Connect your existing platform

Programming interfaces

- REST API

- Python SDK

- JavaScript SDK

- C++ SDK

- Go SDK

- R SDK

- C# SDK

- Java SDK

Messaging protocols

- MQTT

- OPC UA

- MODBUS

- SQL

Amber can be integrated into your existing data management platform for deployment entirely on-premise or in the cloud. All of Amber’s analytics can be visualized in your existing user interface (PowerBI, PI Vision, VantagePoint, etc).

Our supported platforms

Native integration with PI Web API

Native integration with Ignition REST API

Native integration with Azure Event Hub

Native integration with Cumulocity

Data-driven decision making

Paul Chen

Reliability Engineer

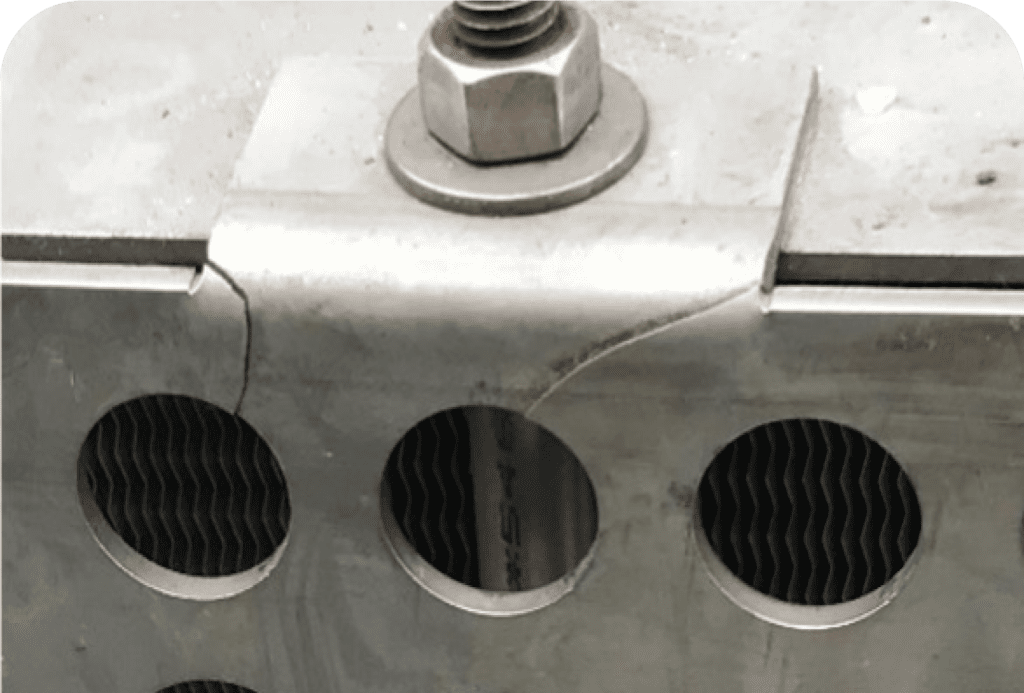

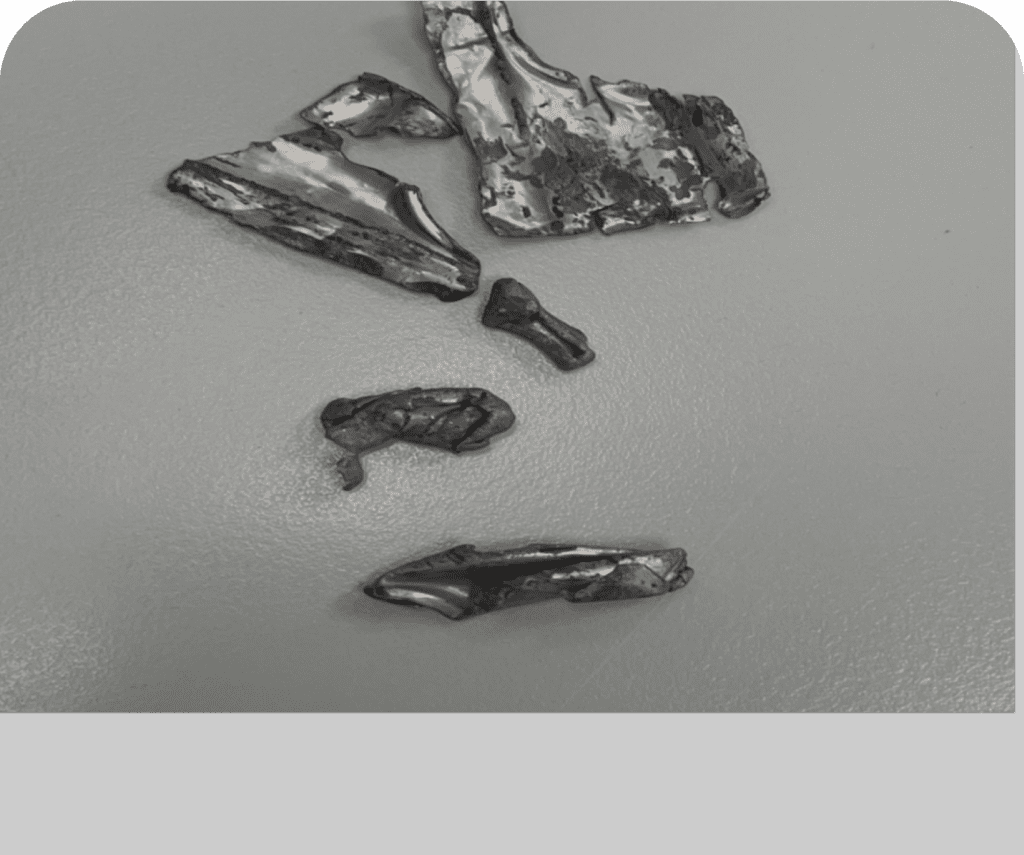

Amber alerted our staff members that they needed to stop and repair their compressor, which they did three months earlier than originally planned. That allowed them to see several cracks on their cooling bundle that, if left unrepaired, could have caused $800,000 in repair costs. Instead, they spent $60,000 to repair the cooling bundle and were up and running in 72 hours.