Real Machine Learning for Visual Inspection

AVIS detects hidden anomalies in complex video and image data streams by autonomously training for the normal instead of the abnormal.

60 minutes

Time to train a new inspection recipe from scratch

No defect sets

Defects aren’t required to train AVIS - only 500 units of compliant product are required for training

1.5 FTE

Replaced on average with every deployed AVIS system

99% Accuracy

Detect defects with up to 100% accuracy and as low as 1% false ejects

Increase quality and productivity with AI-driven inspection

Increase quality and productivity with AI-driven inspection

Enhance quality, consistency, and overall throughput of your operations. AVIS automatically detects defective products with heightened accuracy compared to human inspectors, giving you confidence in the quality of each unit going out the door.

Detecting anomalies is straightforward once you capture all variations that are considered normal. AVIS trains using compliant product instead of labeled defect images. It’s the only practical way to automate visual inspection for the world’s toughest-to-inspect products.

Your challenging use case solved in minutes.

Four steps to create a recipe

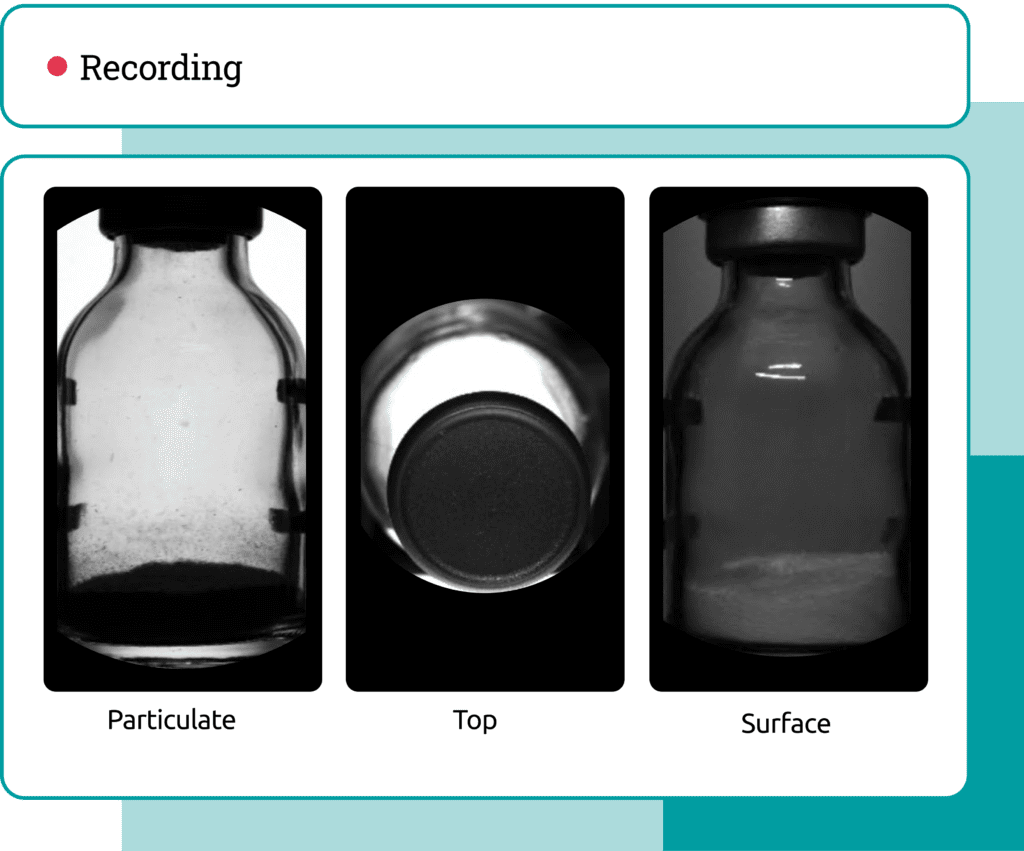

Record

Create a recording of 500 compliant units of product.

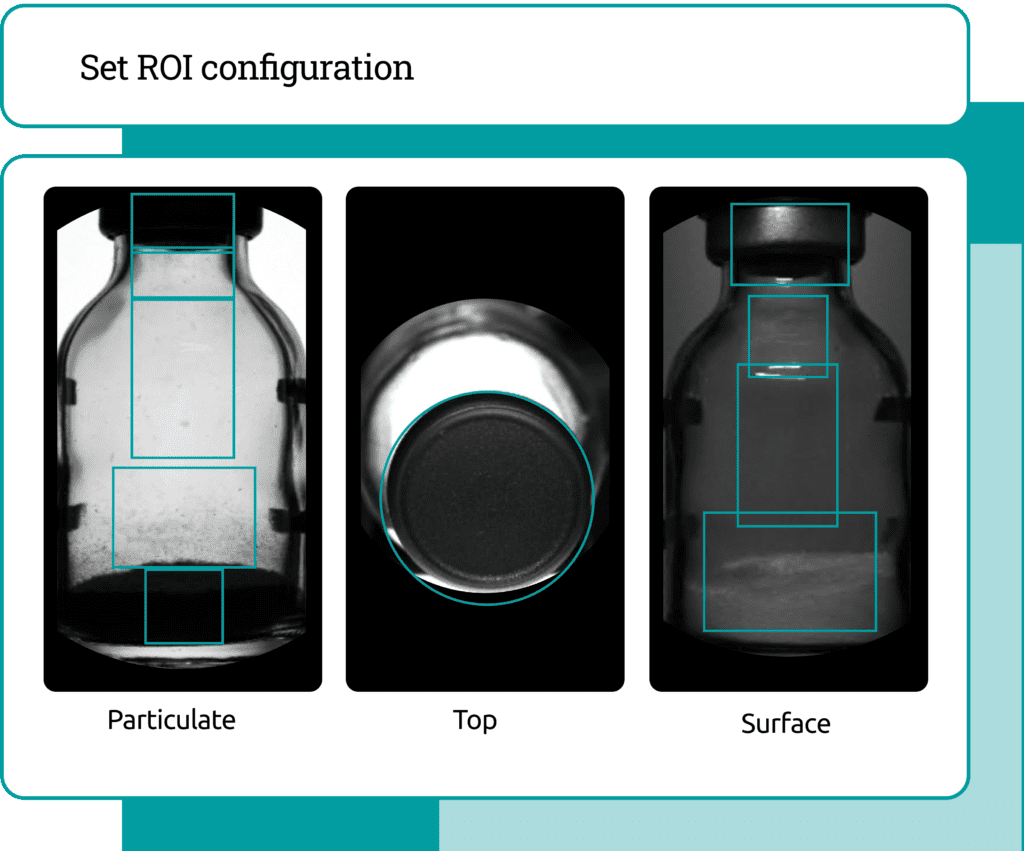

Configure

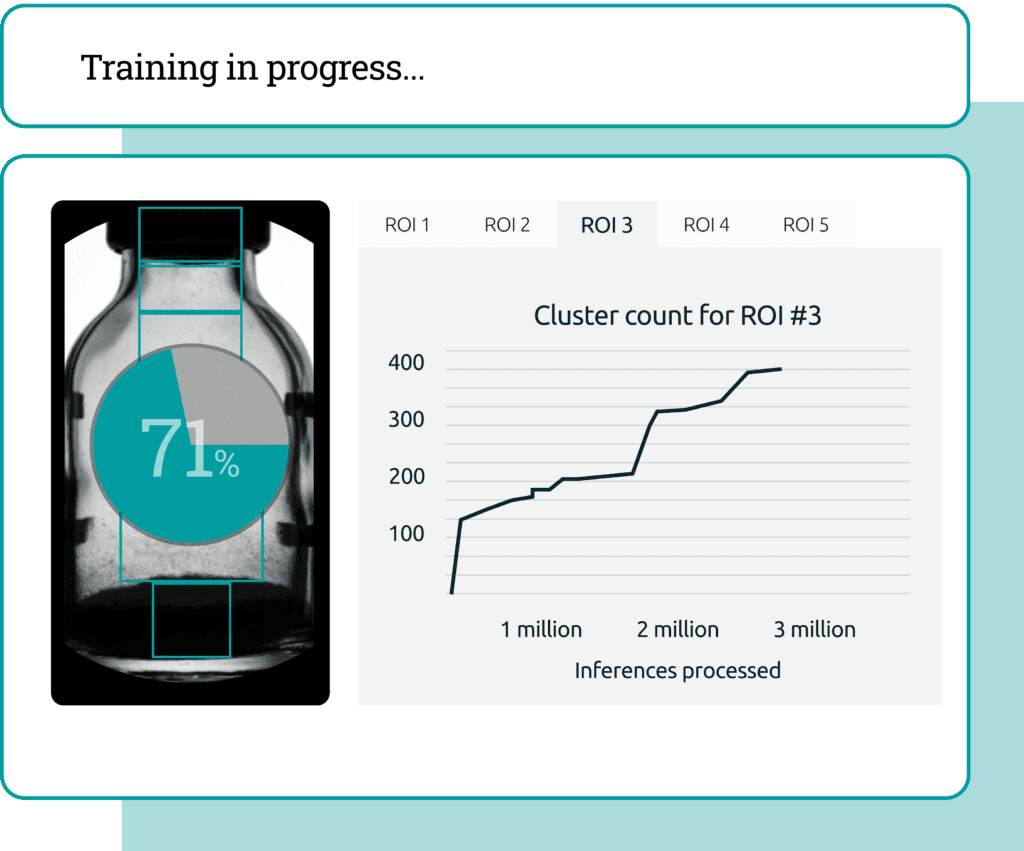

Select regions of interest (ROIs) for all cameras. AVIS creates an individual model for each ROI.

Train

AVIS creates a recipe by autonomously training to recognize all normal variation within each ROI. This typically is complete in less than 15 minutes.

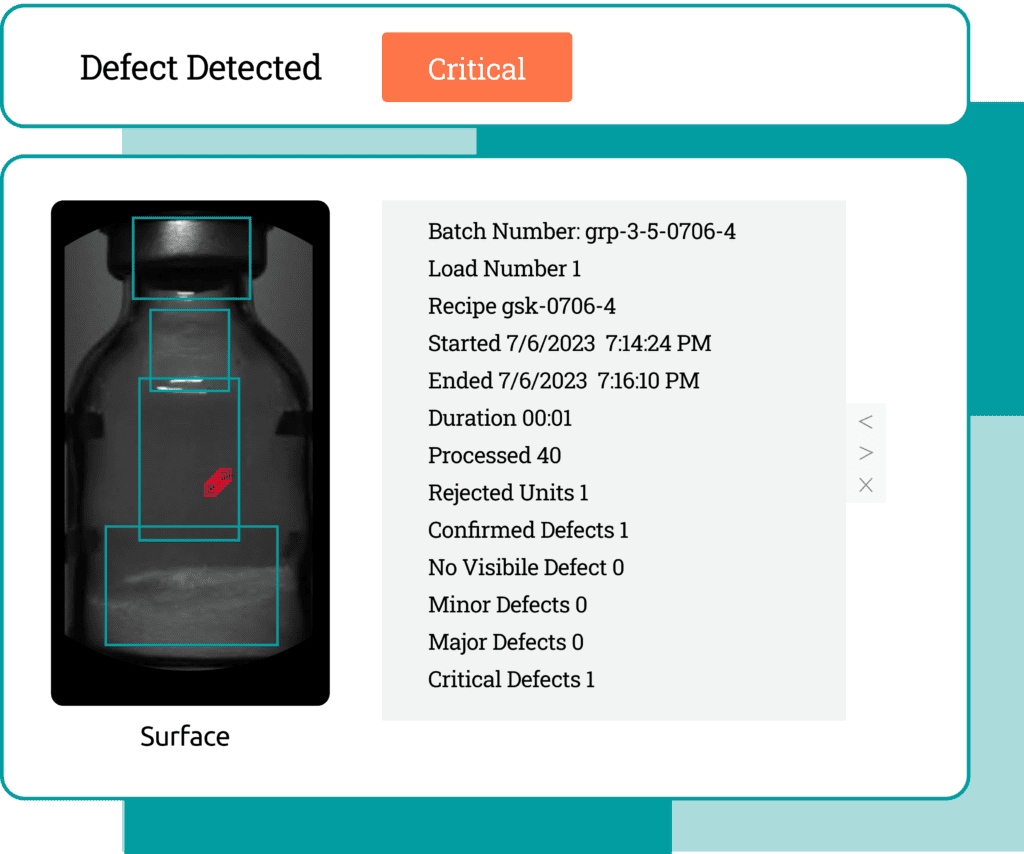

Run

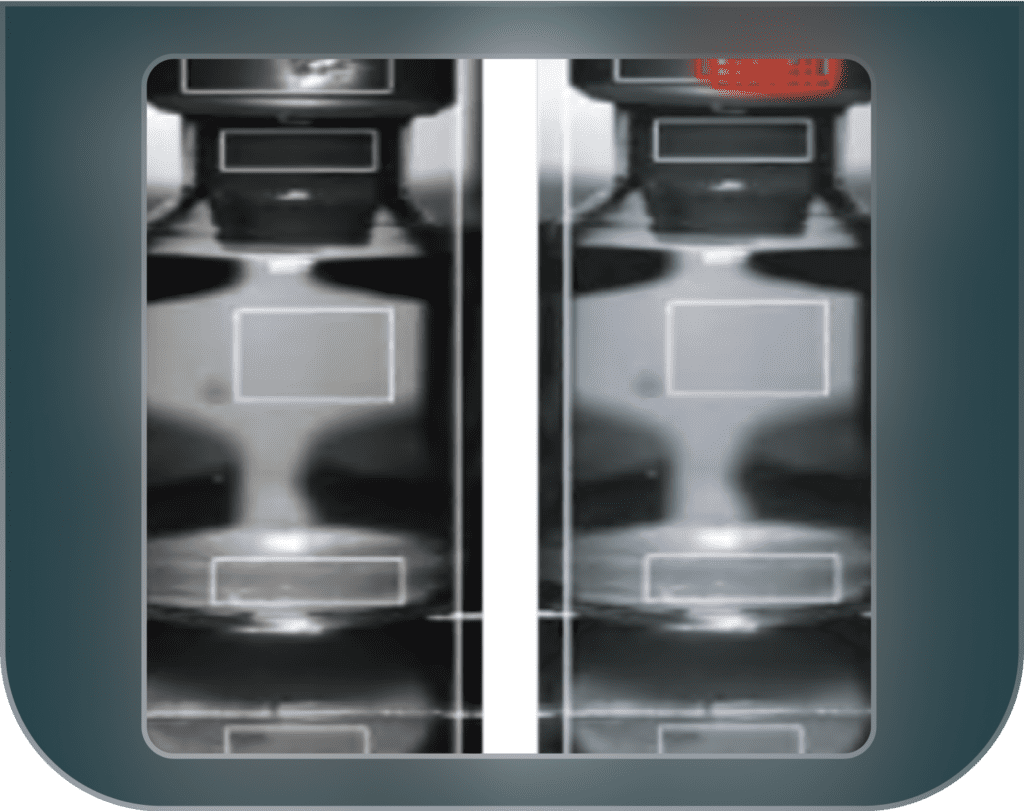

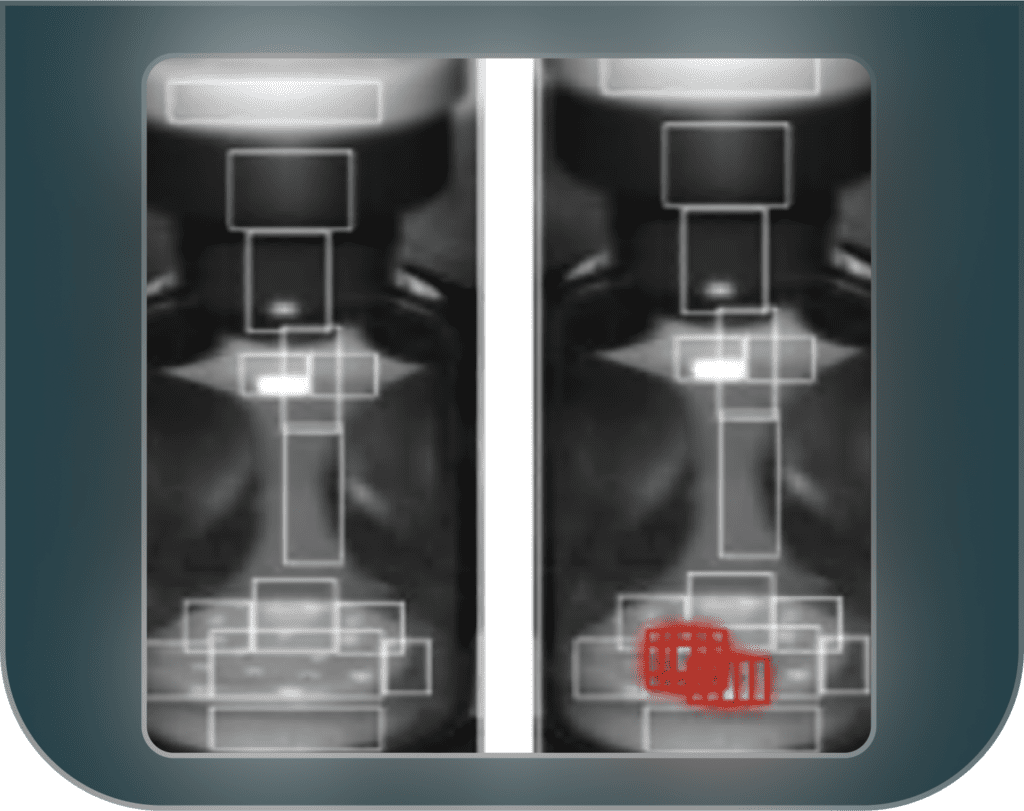

AVIS uses its reference models of normal variation to detect defects which are displayed on the AVIS HMI and archived in the audit trail.

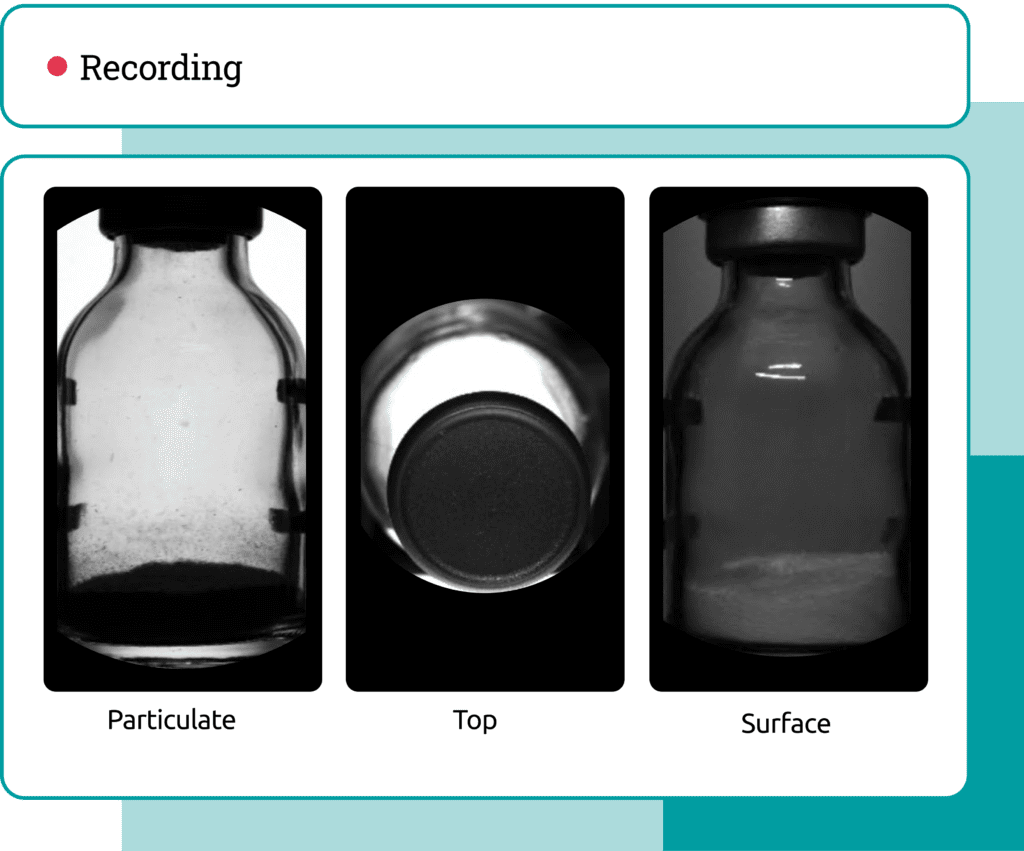

Record

Create a recording of 500 compliant units of product.

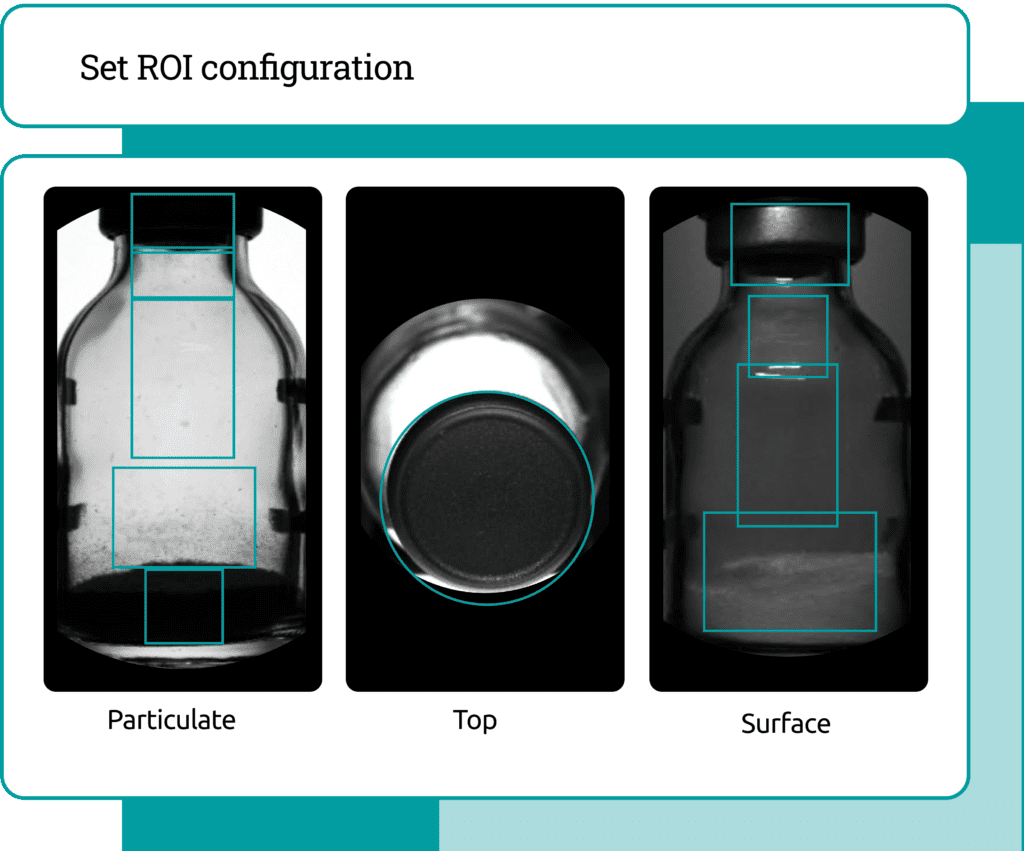

Configure

Select regions of interest (ROIs) for all cameras. AVIS creates an individual model for each ROI.

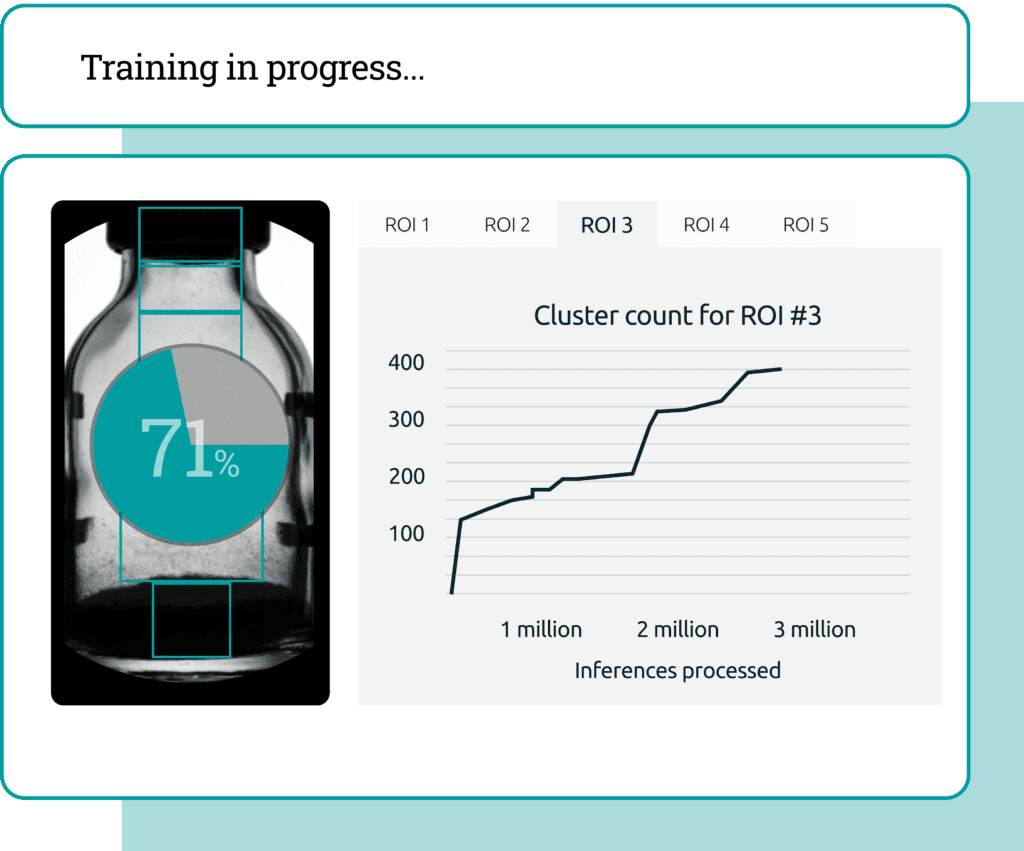

Train

AVIS creates a recipe by autonomously training to recognize all normal variation within each ROI. This typically is complete in less than 15 minutes.

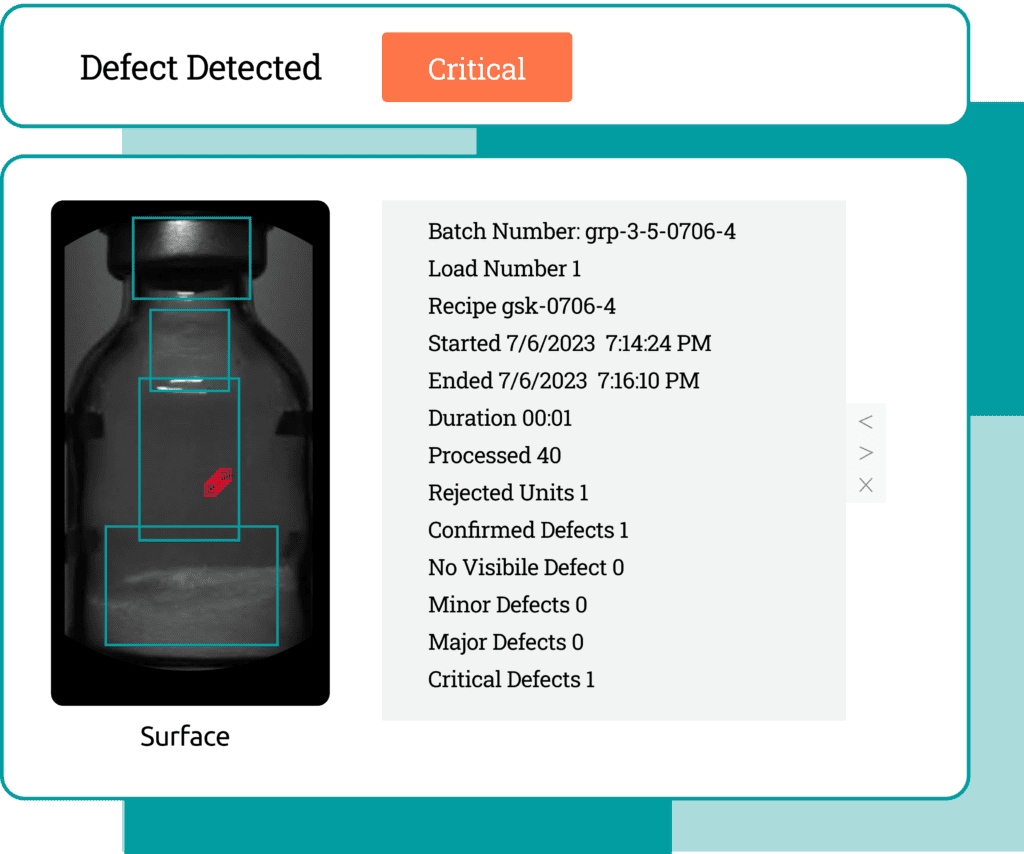

Run

AVIS uses its reference models of normal variation to detect defects which are displayed on the AVIS HMI and archived in the audit trail.

Record

Create a recording of 500 compliant units of product.

Configure

Select regions of interest (ROIs) for all cameras. AVIS creates an individual model for each ROI.

Train

AVIS creates a recipe by autonomously training to recognize all normal variation within each ROI. This typically is complete in less than 15 minutes.

Run

AVIS uses its reference models of normal variation to detect defects which are displayed on the AVIS HMI and archived in the audit trail.

Record

Create a recording of 500 compliant units of product.

Configure

Select regions of interest (ROIs) for all cameras. AVIS creates an individual model for each ROI.

Train

AVIS creates a recipe by autonomously training to recognize all normal variation within each ROI. This typically is complete in less than 15 minutes.

Run

AVIS uses its reference models of normal variation to detect defects which are displayed on the AVIS HMI and archived in the audit trail.

Record

Create a recording of 500 compliant units of product.

Configure

Select regions of interest (ROIs) for all cameras. AVIS creates an individual model for each ROI.

Train

AVIS creates a recipe by autonomously training to recognize all normal variation within each ROI. This typically is complete in less than 15 minutes.

Run

AVIS uses its reference models of normal variation to detect defects which are displayed on the AVIS HMI and archived in the audit trail.

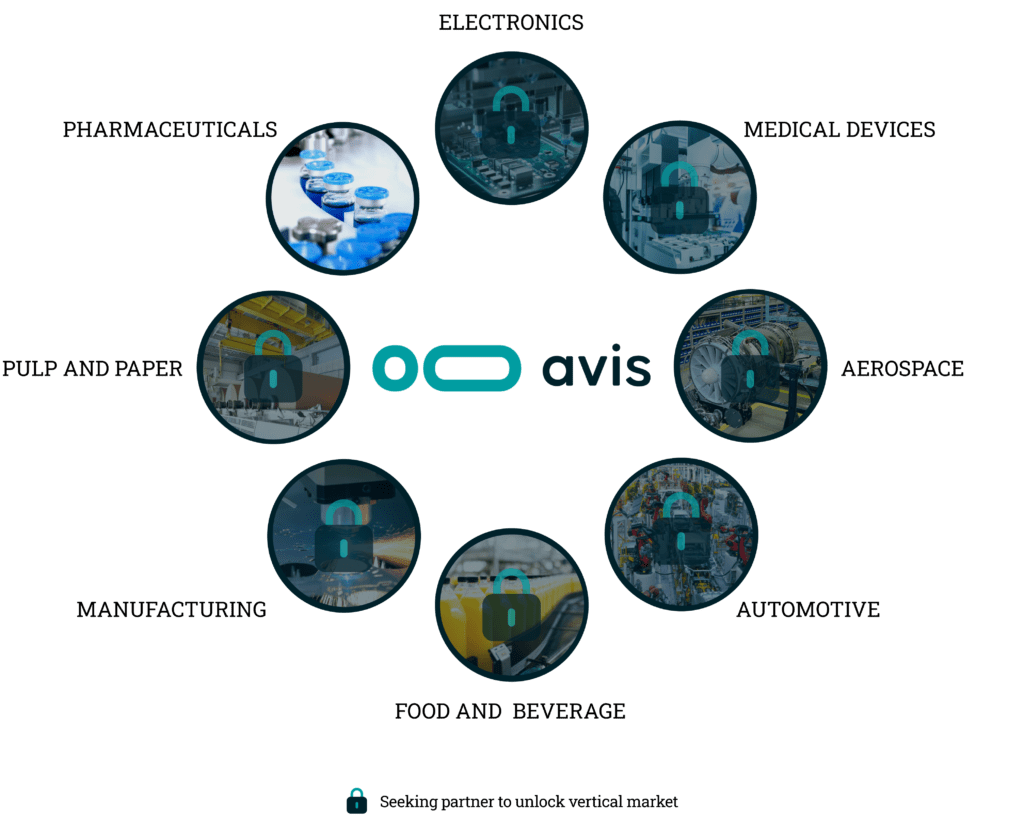

Industry-specific solutions brought to market by strategic partners

Unlock new solutions by becoming a Partner today

Partnered Solutions for Pharma

Built by

DABRICO

Built by

GENESIS PACKAGING TECHNOLOGY