The Next Generation of AI-based Visual Inspection in Pharma

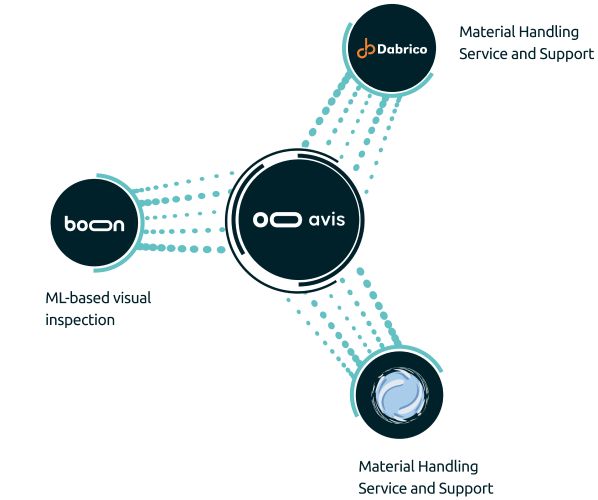

In partnership with leading machine builders, Dabrico and Genesis Packaging Technologies, Boon Logic introduces a new approach to automated visual inspection built for the toughest inspection use cases.

The most powerful partnership in

Pharma vision

With over 100 combined years in Pharma, Dabrico, Genesis Packaging Technologies, and Boon Logic have partnered to tackle the toughest visual inspection challenges. Our partnership combines the material handling, service, and support expertise of Dabrico and Genesis Packaging Technology with Boon Logic’s cutting-edge software for unsupervised ML-based visual inspection, AVIS. Whether retrofitting an existing SAVI or deploying a new line for upstream or downstream inspection, we have you covered.

Pharma vision reimagined

ML-based automated visual inspection

DAI-50

Built by Dabrico powered by AVIS

- Compact 36″x36″ automated visual inspection machine

- Three camera, AI-based inspection at up to 50 vials per minute

- Train a recipe for new products in one day

- No AI or computer vision expertise needed

- Trains from compliant units (no defect sets needed for training)

- Integrated material handling system and ejection

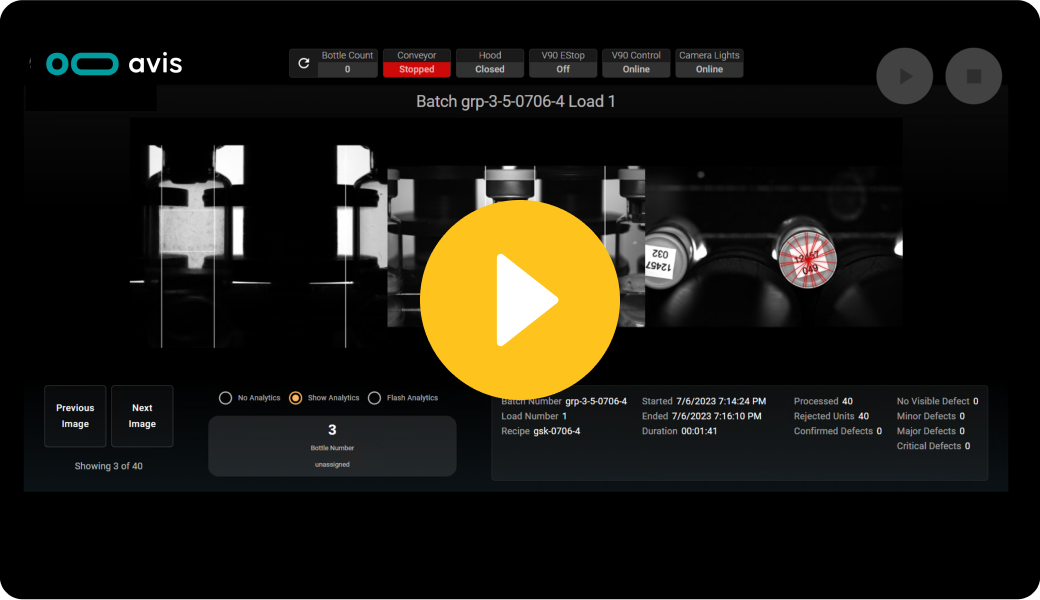

Advisum-AI

Built by Genesis Packaging Technologies powered by AVIS

- Mounts into operator inspection cabin turning SAVI into AVI

- Three camera, AI-based inspection at up to 50 vials per minute

- Train a recipe for new products in one day

- No AI or computer vision expertise needed

- Trains from compliant units (no defect sets needed for training)

- Currently available for the Seidenader V90 (ask about other SAVI machines)

- -integrates with SAVI conveyor control and ejection system

Built for the toughest

Inspection use cases

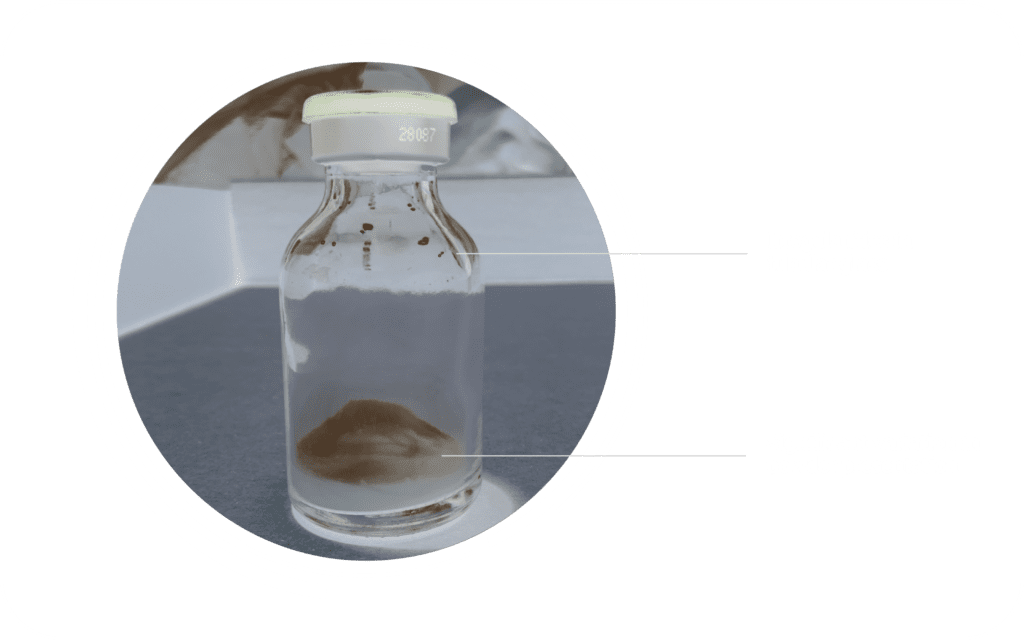

Powder and lyophilized product

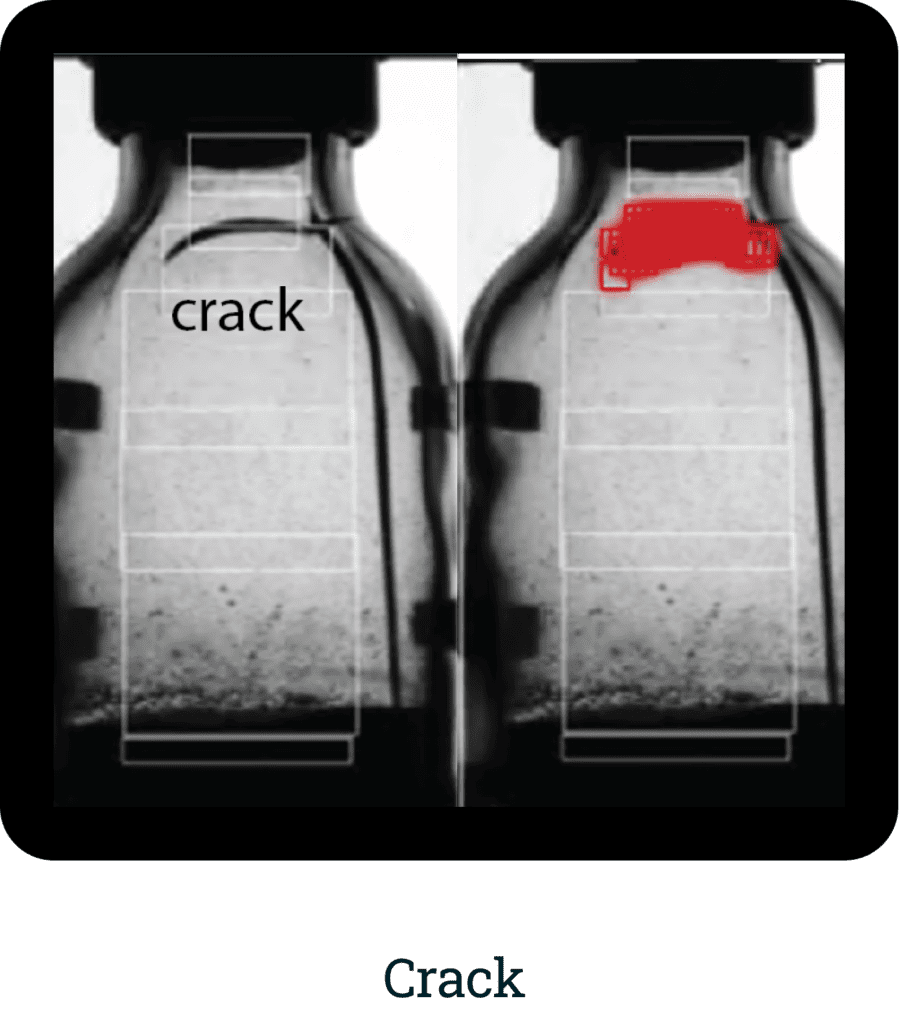

Tubular and molded glass

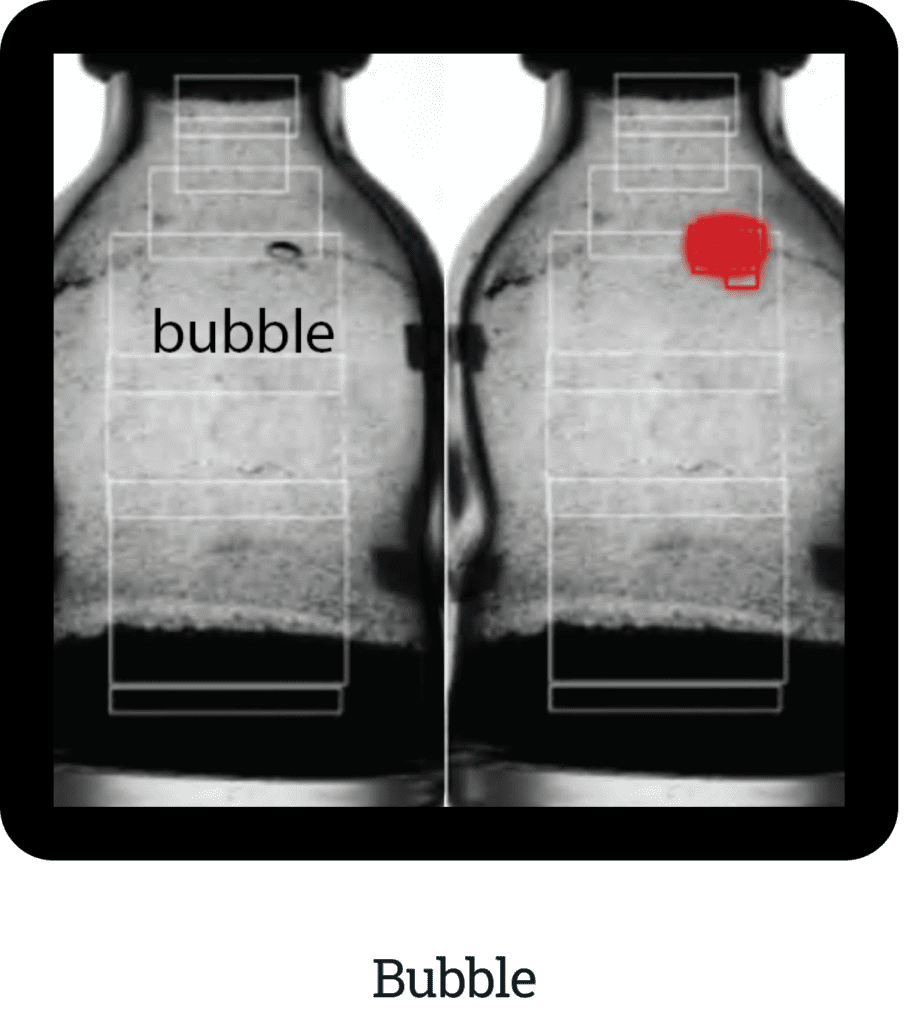

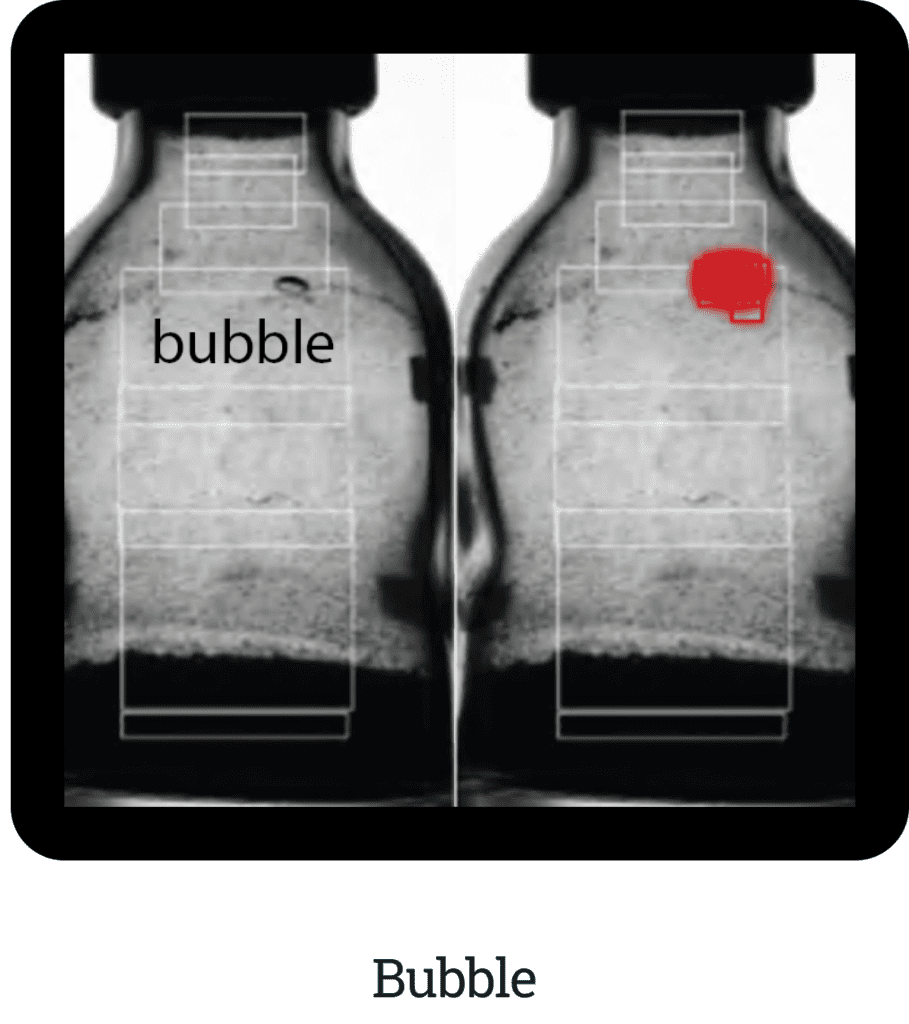

Liquids prone to bubbles

Translucent plastics

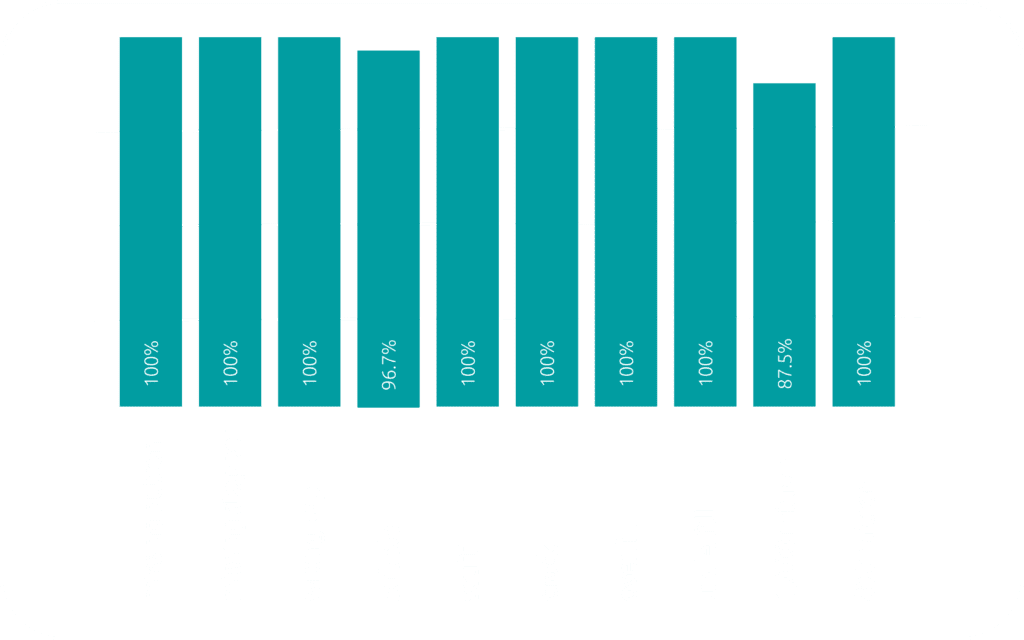

Detection results

20 ml with Powder Product

Product type

Challenge

Solution

AVIS learns all of these normal variations and automates the visual inspection process enabling the customer to scale production without hiring more human inspectors.

Results

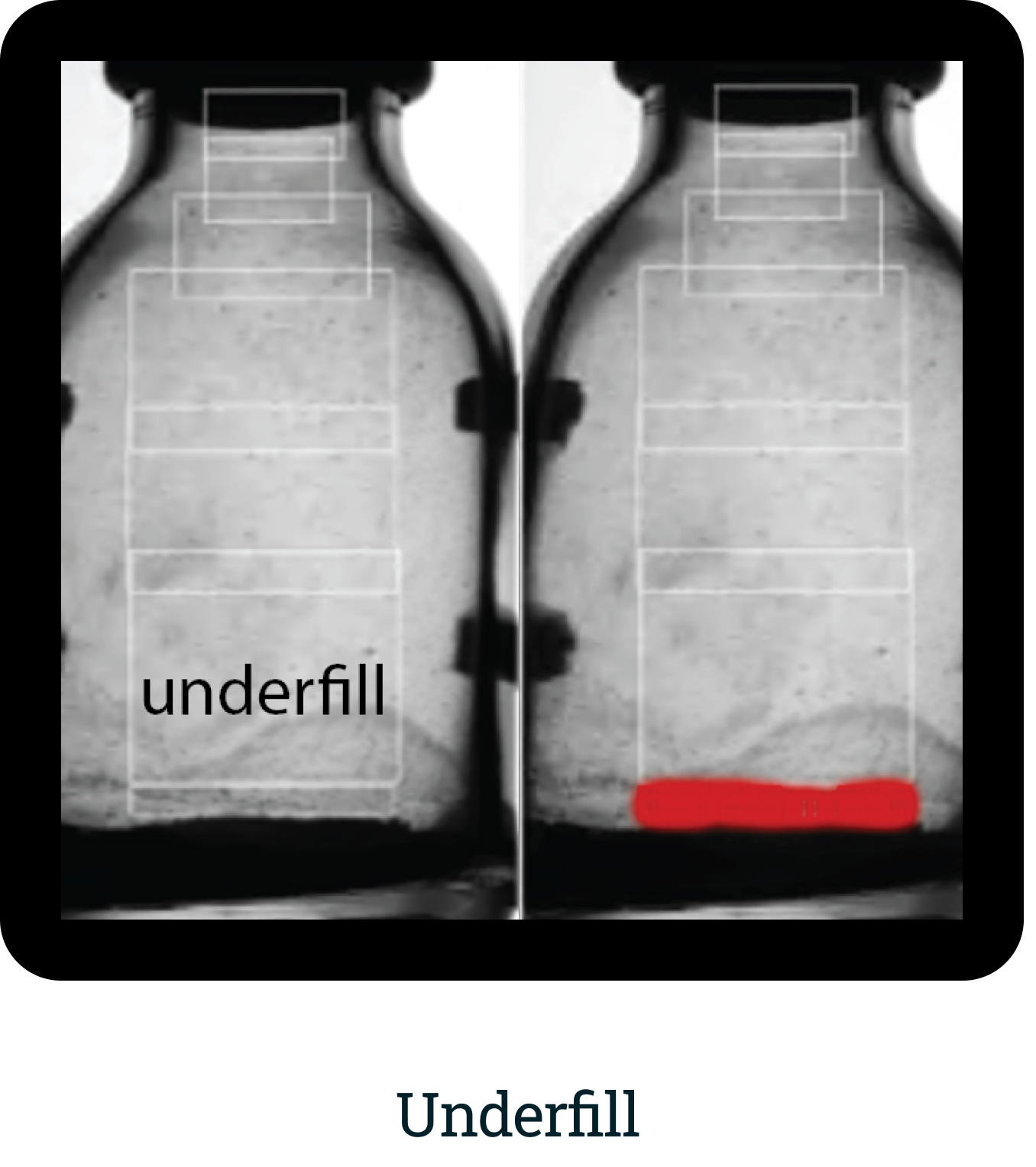

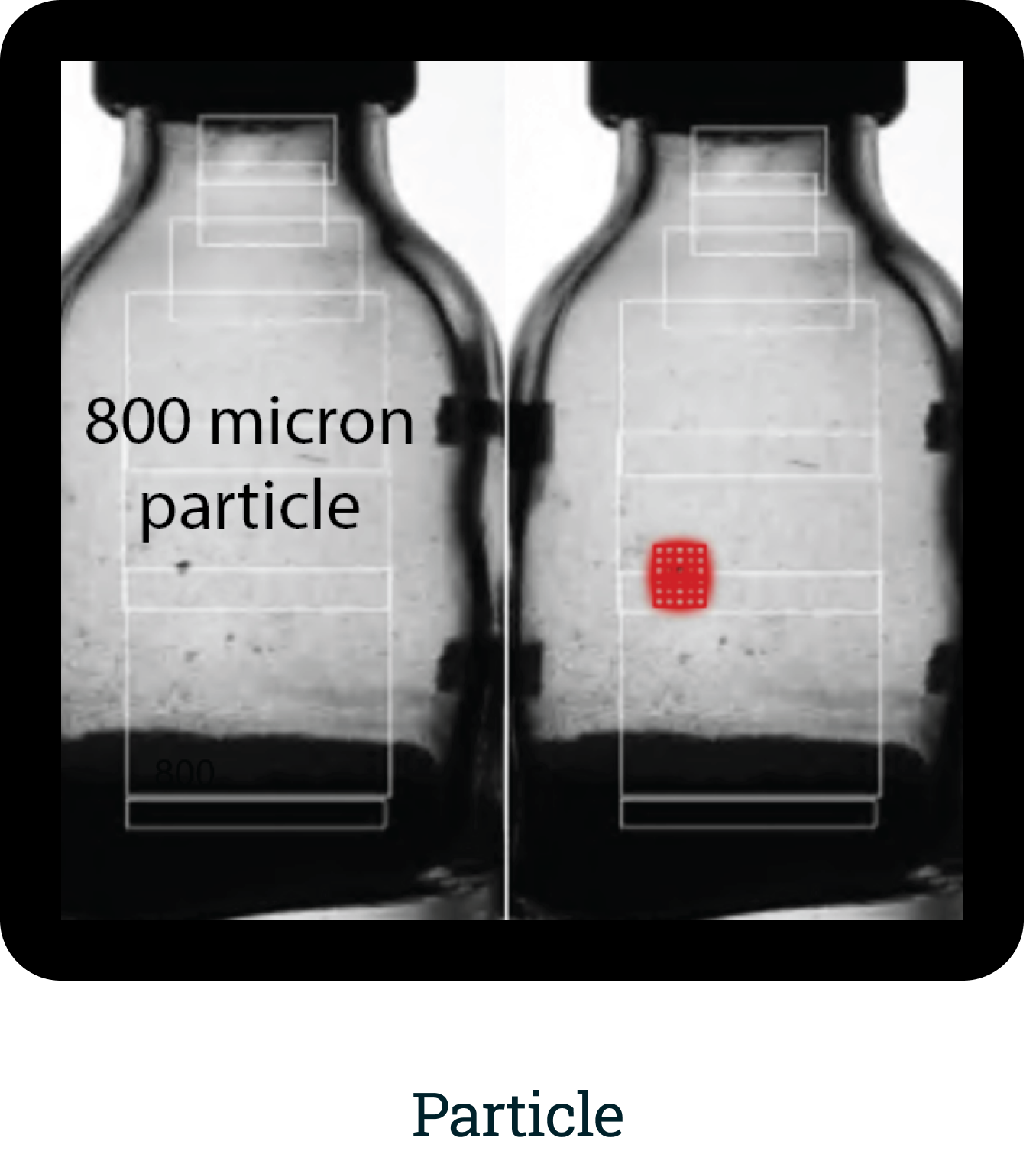

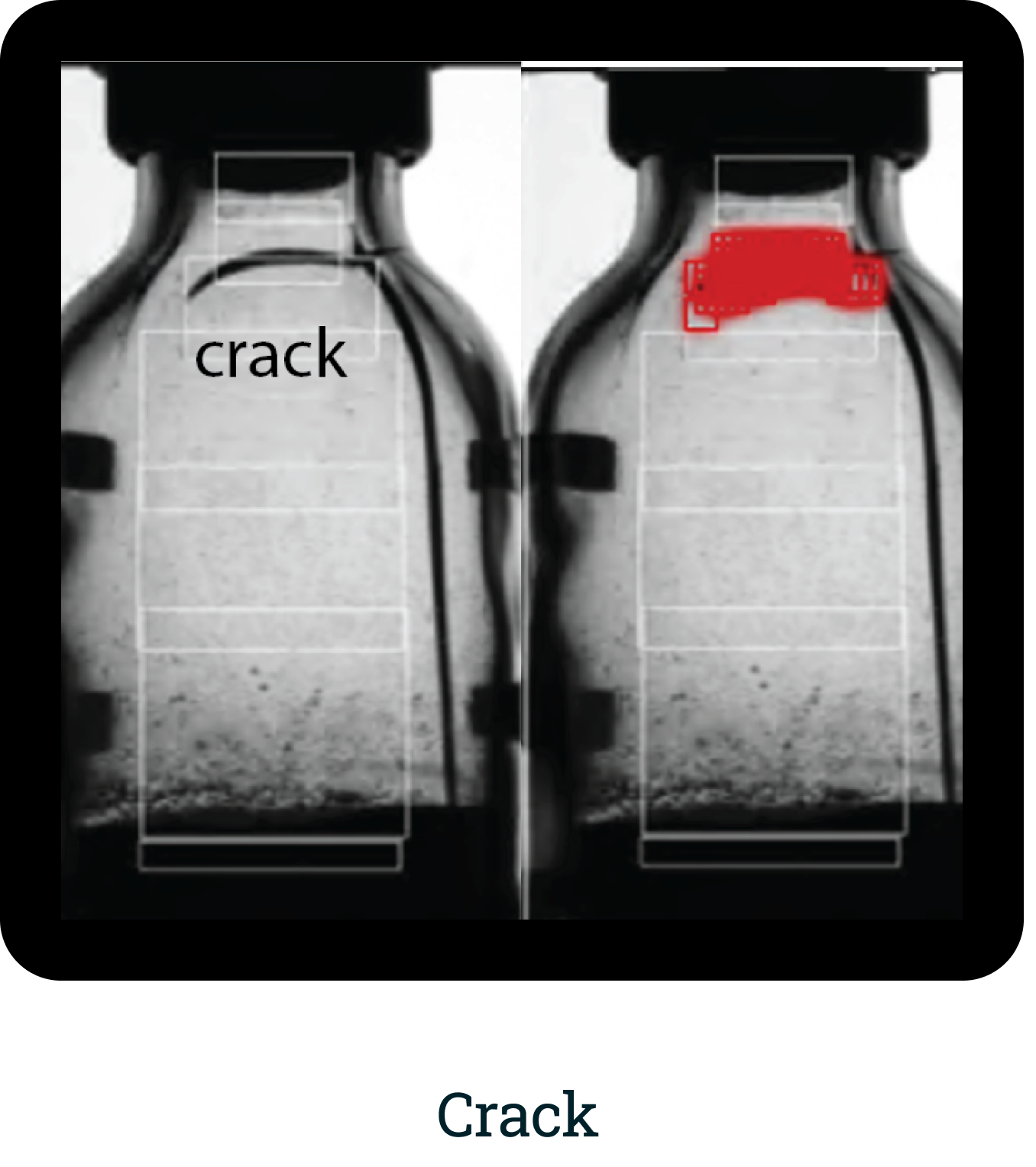

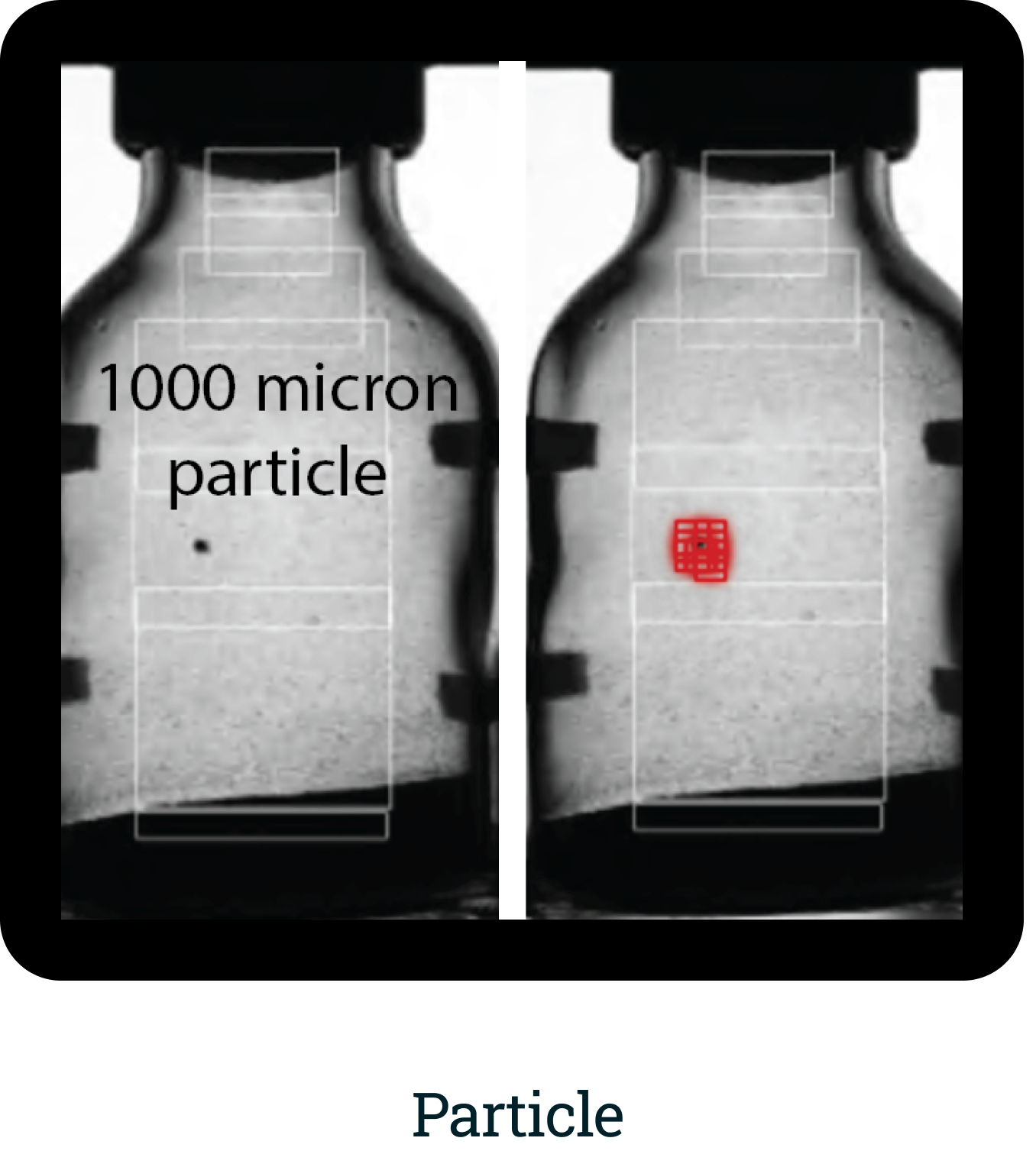

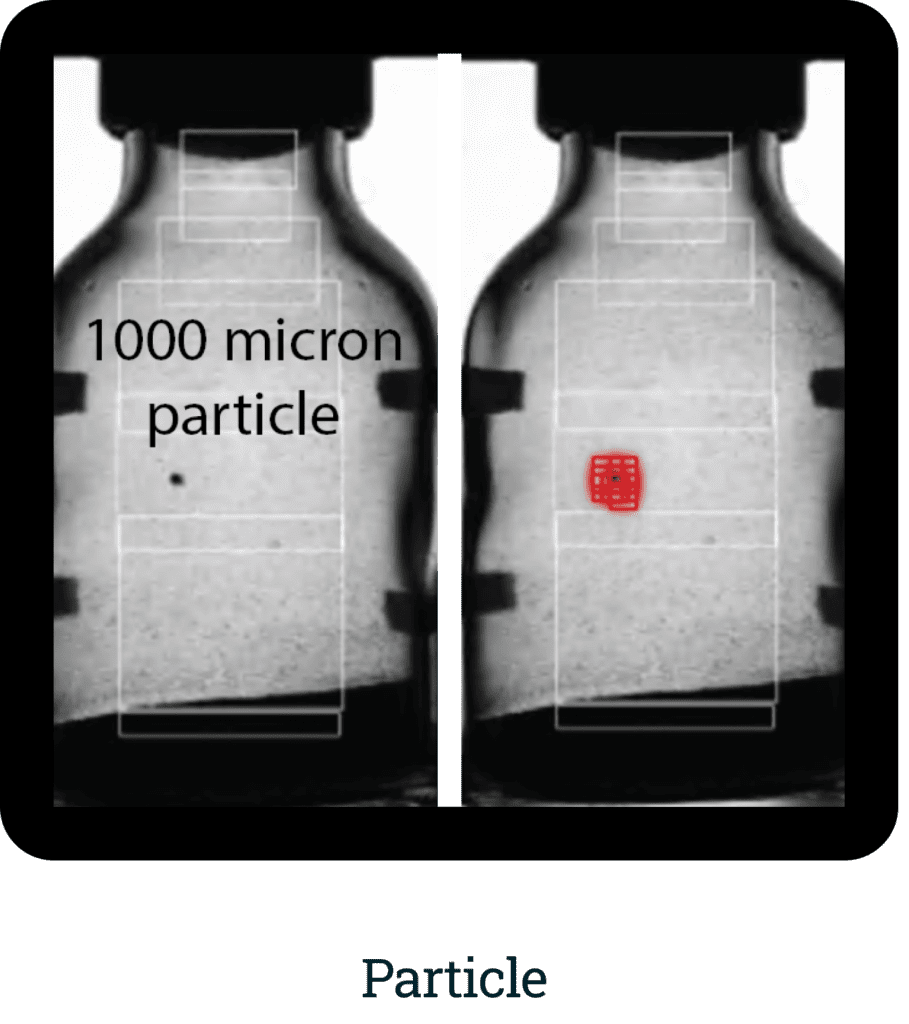

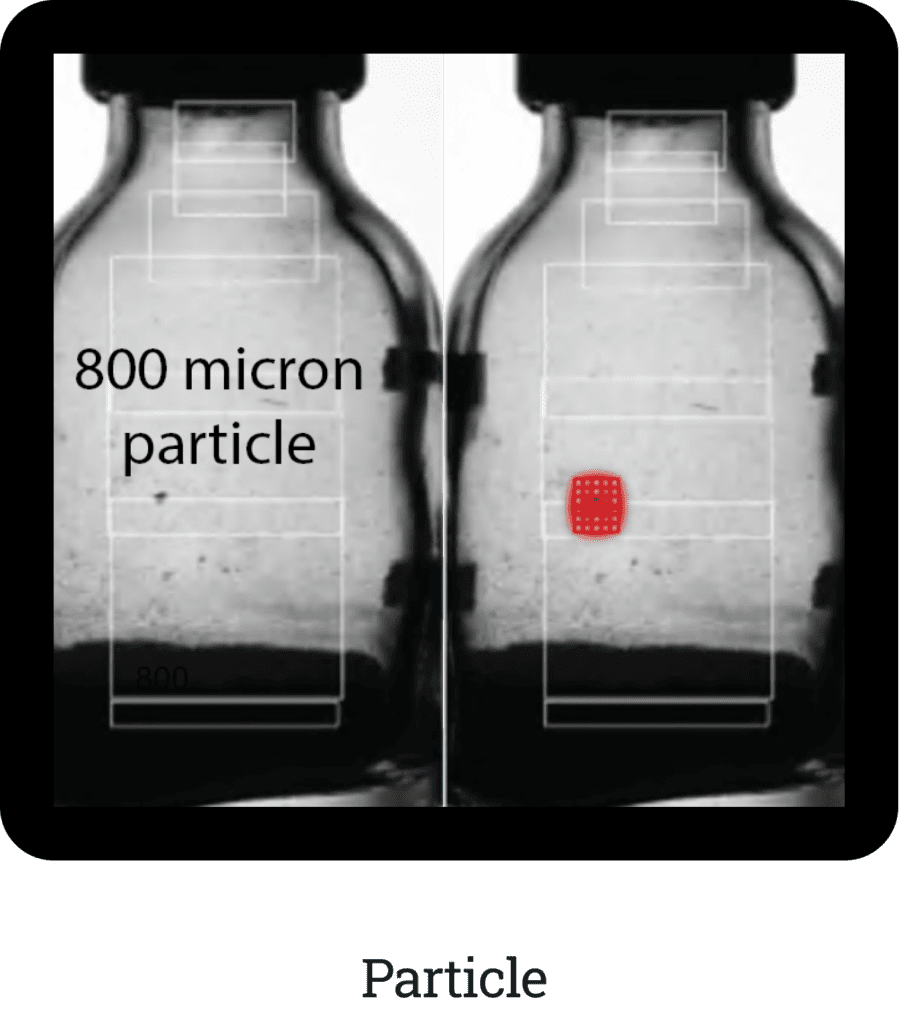

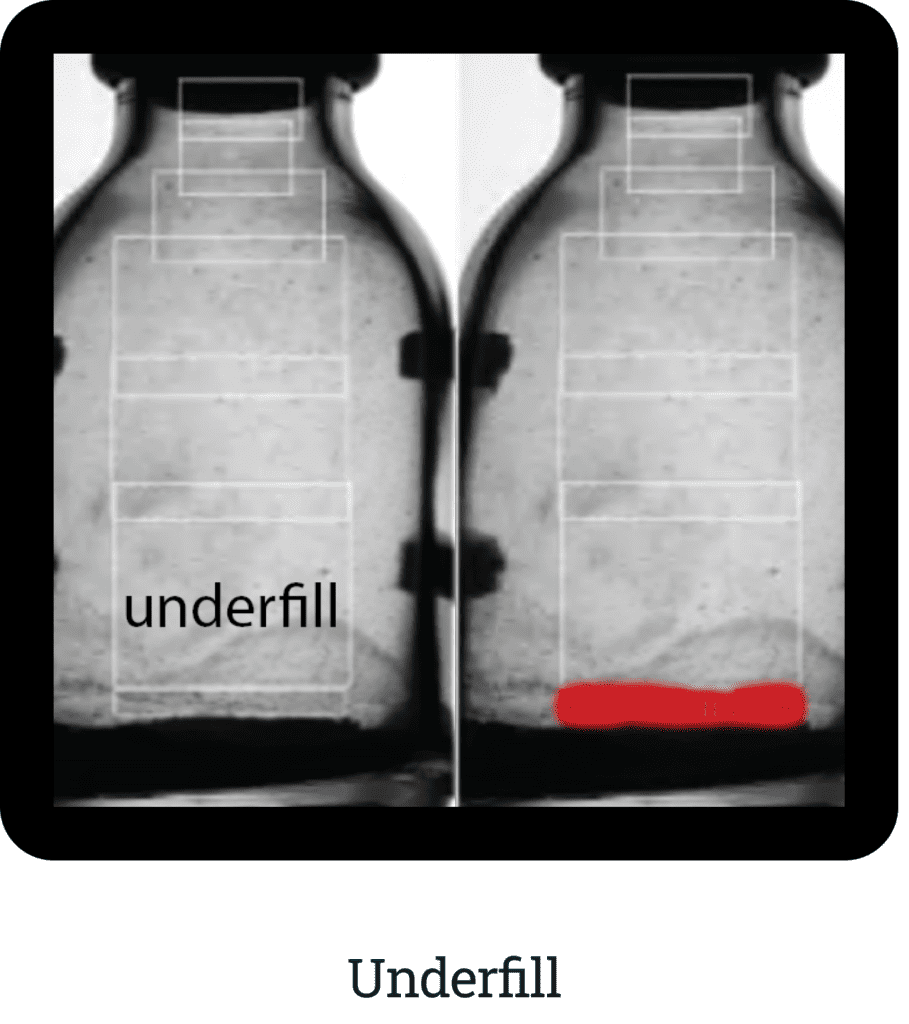

AVIS detected 98% of all defects with a false eject rate of 2.7%. Particles below 600 microns were learned as compliant powder deposition whereas anything above 800 microns was detected as a defect as this was not present in the training set.

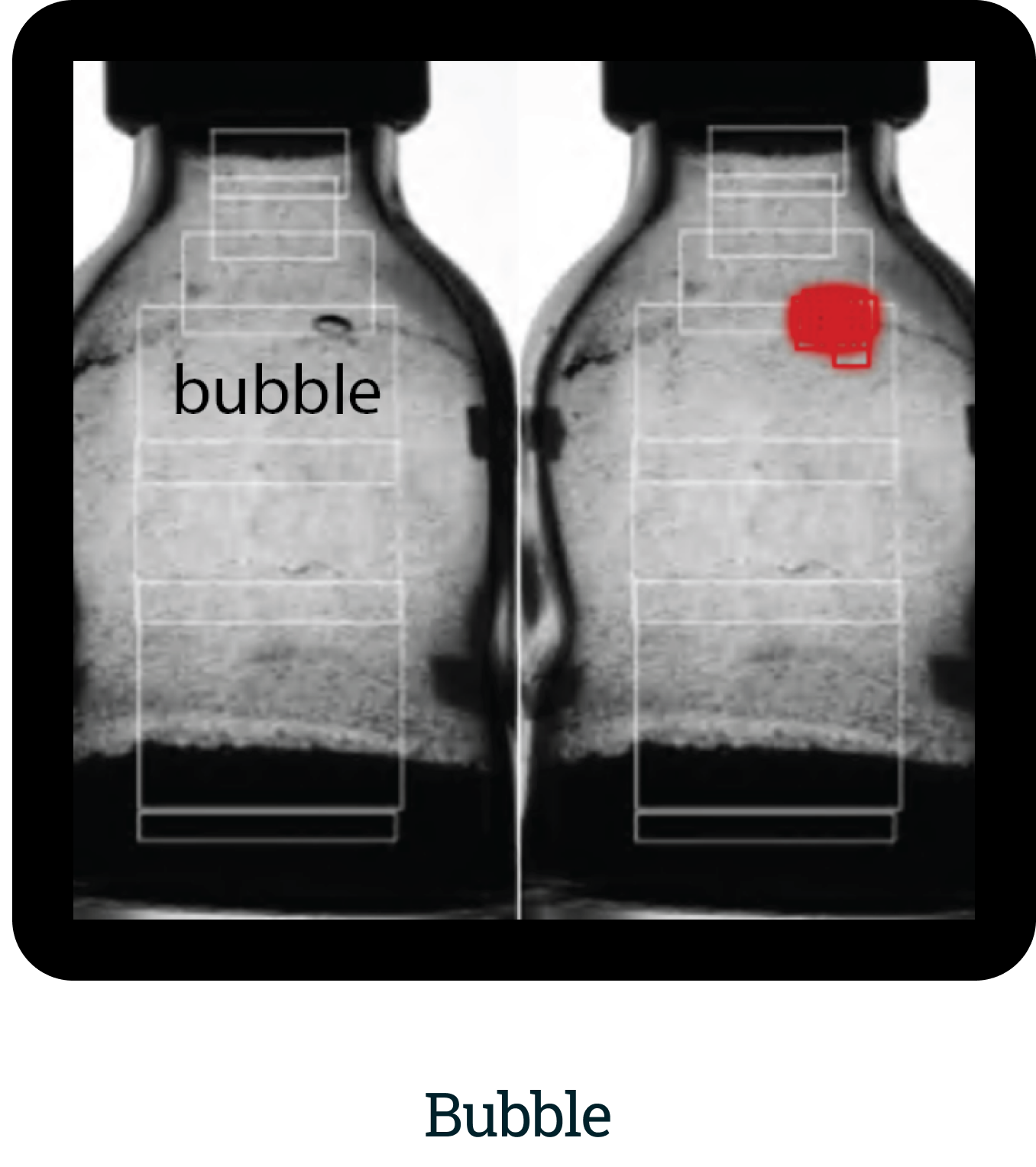

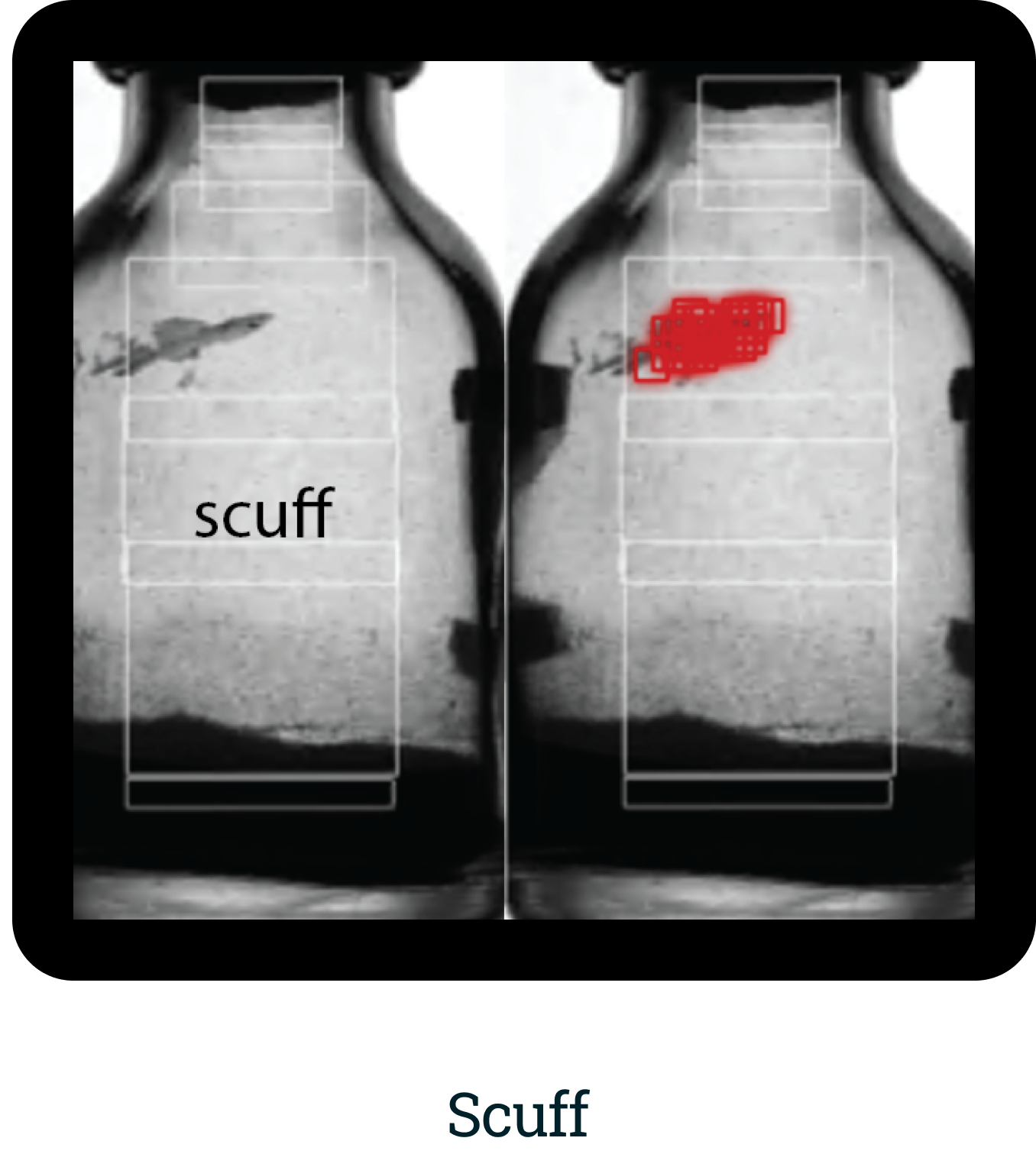

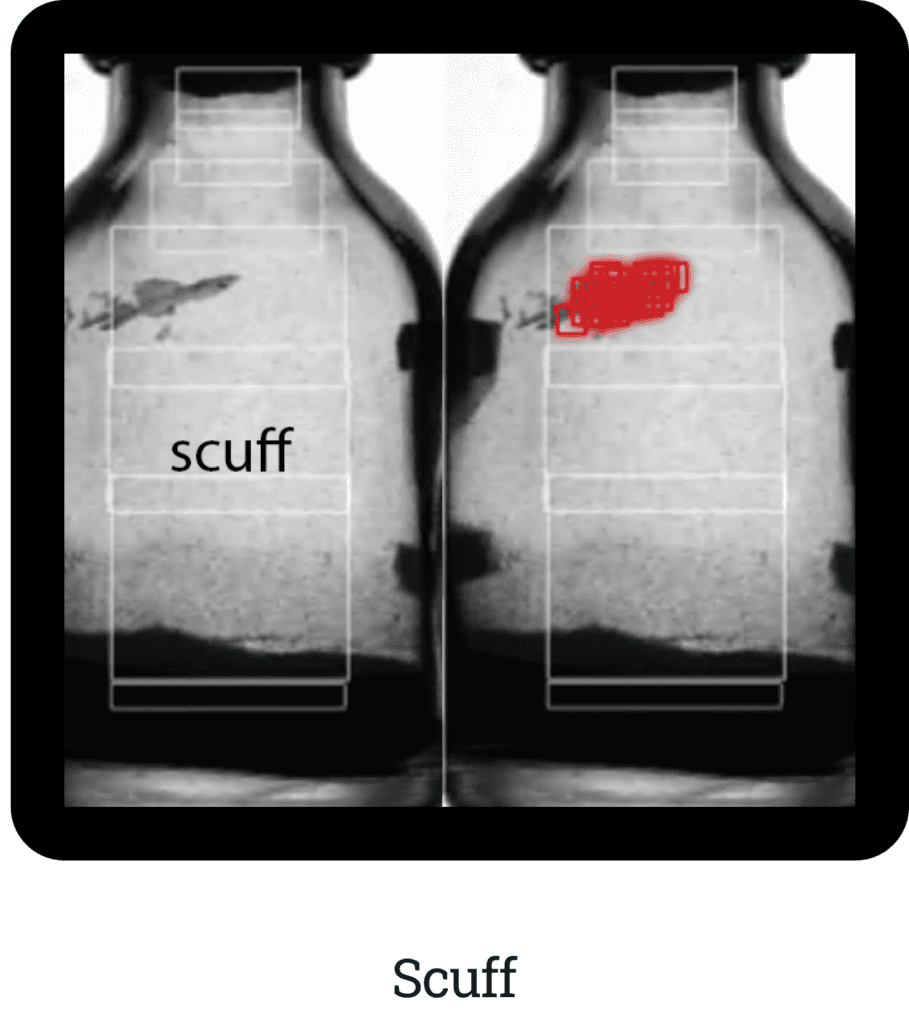

Examples of detected defects

Examples of detected defects